According to industry experts, the global internet of things (IoT) market is expected to reach USD 724.2 Billion by 2023. This has led to an overwhelming demand for IoT-ification or rather IoT enablement of the businesses.

But at the same time, a great number of IoT projects do not result in desired outcomes, even after investing a great deal of time and money .

These failures generally occur due to crucial solution design mistakes, that can derail the success of your IoT Implementation.

Wondering what are they? With the help of our IoT consultants, we have put together a list of must-avoid IoT system design mistakes.

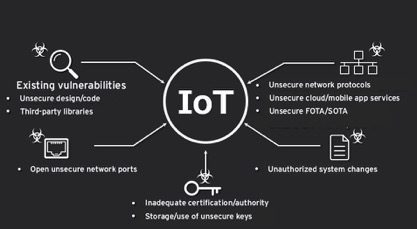

Not Making ‘System Security’ Part of the Solution at Design Stage

As an IoT product development team, you should not take the risk of not integrating the security aspect at the design phase. Because it is very challenging to integrate security best practices with the IoT application/product during the deployment stage. This often results in below-par quality and robustness of the IoT application.

IoT networks are highly vulnerable and any loop-hole in security can result in loss of critical industrial data.

What makes the security of an IoT system robust? Answer lies in system integrity and verified/authentic access control of the IoT devices.

One should clearly define the data routing protocols for secure data exchange, data encryption mechanisms, data authentication and access control features.

Security Issues in IoT. Image Source: Trend Micro

Operating Environment of the IoT Devices

While designing an IoT solution, one needs to be well aware of the operating environmental conditions where the IoT devices will be deployed (open fields, industrial assembly lines etc.).

Information about the fluctuations in temperature and moisture levels, ambient heat will help the design team to identify the required product casing type and quality grade.

This will help you in taking adequate precautions at the IoT design stage itself to pre-empt any device damage due to a bad weather or over heating conditions.

Imagine that you are designing an IoT solution for remotely managing the solar trackers in the field. You have designed the solution as per the best practices related to all the hardware and software aspects. But you missed the ambient environment factor. In this case, if the solar tracker that is being deployed in a site which receives heavy rainfall or strong wind, the system may get damaged.

Additionally, the design considerations of your IoT solution should also be able to handle the scenarios of power failure, primary communication failure with necessary fail-over strategies in-built in the design

- Flexibility in Software Codes takes the Backstage

An ideal practice while writing software code for any application, especially if it involves data centric systems like IoT, is to make it as flexible and adaptable as possible. This will ensure that the IoT application is able to support any changes in hardware or a peripheral device without extensive rewriting of the software codes.To ensure adaptability of the software code to the changing needs of the customer, a modular software architecture should be designed. This means in order to effect certain changes, you would not have to rewrite the entire software code, but only the module that is directly connected to the component that needs to be changed/modified.

Yet another thing to be borne in mind is the power efficiency of the software code. This has an impact on the longevity of the devices in the IoT network.

This is because power inefficient IoT devices can become victim of the below-par longevity.

Lack of Data Fidelity within the IoT System

In IoT systems, data reliability plays a very important role. An efficient IoT system involves error-free, reliable data communication at all levels- namely, the devices, the gateway, the cloud server and the user interface.

When we say reliable data communication, it involves data fidelity and integrity throughout the IoT network.

Data fidelity means data from sensor to the gateway matches with the data transferred gateway to the cloud server. Verifying the data fidelity helps in determining whether the data has been altered during transmission across the IoT network & this is done at the software development level.End-to-end data fidelity can be ensured through data acknowledgment techniques such as cyclic redundancy check (CRC) at each reception point.

Also, your IoT system should have an efficient data backup & recovery plan in the event of a software or network failure.

Ignoring the Longevity of Hardware Components

When you design the hardware you should check the validity and longevity of each and every component being used for the design. It should not happen that by the time your IoT application is ready to be deployed; the hardware component that you have sourced from a particular manufacturer has gone obsolete or is no longer available in the market. Such a situation can halt your entire project.

So, at the design stage itself you should ensure that hardware components , that are part of the IoT solution, are available in the market for a long period ( say, 5 to 6 years atleast) and has guaranteed aftermarket support and maintenance service from the manufacturers.

Inadequate IoT Testing Practices

Testing plays a major role in ensuring a reliable operation of the IoT devices.

You should have a comprehensive test plan ready for your IoT application. And IoT testing must be done at different levels- the data , the hardware, the peripherals, the software, the network, the firmware, the user interface- to ensure that the product will work.

Typically, a highly information intensive system like IoT, which stores and processes large volumes of data and has to sync-up with large number of devices, would require extensive testing mechanisms such as regression testing, endurance testing, functional testing and unit testing.

Additionally, you should perform, vibration test, drop test, pressure test- mandatory to ensure that your field deployed IoT devices are working efficiently.

Checking the Regulatory Requirements & Certifications at the 11th Hour

Before proceeding to the production, you must ensure that your IoT application, including the various ( software & hardware) components involved in developing it, is compliant and certified with regulatory requirements.

Standard certifications include – CE, UL (Underwriters Laboratories), FCC, CSA (Canadian Standards Association), ROHS (Restriction of Hazardous Substances) and the likes.

Certifications Relevance Symbol CE Certification The CE marking signifies conformity with health, safety, and environmental protection standards for products manufactured in, or designed to be sold within the European Economic Area (EEA).

UL (Underwriters Laboratories) Listing Mark The UL mark is a certification to ensure the electrical safety of a particular product or component (Electrical and Electronic Products, Industrial Control Equipment, Wires and Cable etc. )

FCC( Federal Communications Commission) Mark The FCC label is mandatory for electronic products manufactured or sold in the United States and certifies that the electromagnetic interference from the device is under limits.

CSA (Canadian Standards Association) Certificate The CSA certification is necessary for all electrical and electronics products to be sold or installed in Canada. The CSA standards certifies a product against fire hazard, mechanical hazard, and shock or energy hazard.

ROHS (Restriction of Hazardous Substances) Directive The RoHS directive puts restriction on use of certain hazardous substances in electrical and electronic equipment. Any RoHS compliant product is tested for the presence of Lead , Cadmium, Mercury, Hexavalent chromium , Polybrominated biphenyls, and Polybrominated diphenyl ethers.

At the design stage , you can plan your certification process & timelines. Wherever possible go for pre-certified components so that you can save on cost and time on procuring the certificate at the last moment.

Compromising on the Quality to Save Cost

In a bid to trim down the bottom line costs, you might be tempted to make few design compromises which could end up in sacrificing the quality of your IoT application. This is a must-avoid in order to build a quality IoT product.

Quality management and cost savings can and in fact should go hand in hand. What you save at the design stage might have to be spent on post-deployment troubleshooting and bug fixing activities.

At the design stage itself, you can chalk out an effective plan to develop a high grade application using efficient design components (hardware & software) at an optimal cost. Your design plan must distinguish between design components with high returns and are deemed necessary, from low priority components for which low-cost alternatives are available in the market.

Hope this blog was a good read for you and offered you some food for thought on important design considerations necessary to be taken care of, before plunging into a full-fledged deployment. Would you like to learn more about the IoT implementation? Contact us.