Motor Controller for Electric

Vehicles – E-Autos, 2 Wheelers

and 3 Wheelers

We develop customized motor control solutions to operate modern electric vehicle powertrains cutting across motor types such as BLDC, PMSM, SRM and induction motors. Our proven expertise and proprietary reference designs in the development of advanced algorithms like FOC, Field-weakening and regenerative braking ensures substantially reduced turn-around time for your EV program.

Our team has delivered customized motor control solution along with platform software, diagnostics protocols, and low-level drivers to Electric Vehicle projects across the globe. Since we provide end-to-end motor control solutions development, we respond swiftly to the requirements of our customers. So, if you have a preferred MCU for the platform or wish to design a bespoke motor drive algorithm, we have you covered!

Every motor control solution that we develop is unique in terms of peak and continuous output, operating voltage, safety features and other parameters. Our team ensures that we meet every requirement within strict timelines by taking smart and timely decisions.

[Demo Video] How our Experts Use FOC Algorithm to Overcome the Speed Error in Motor Control Solutions

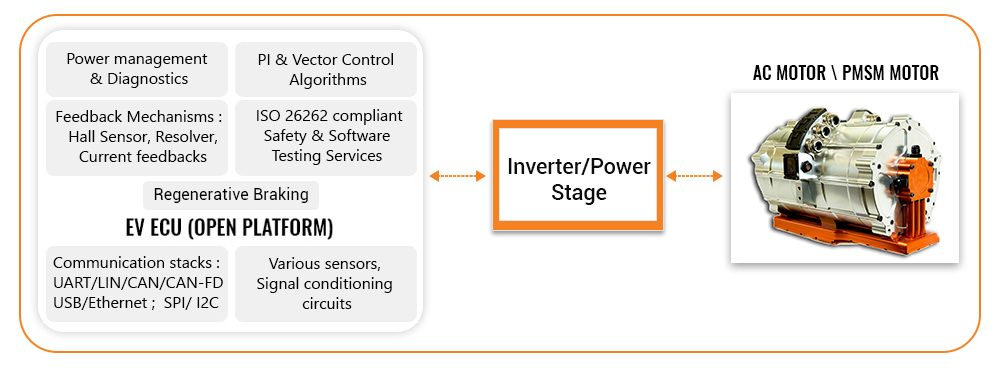

Closer Look at Software and Hardware Components of An EV Motor Controller

- Microcontroller unit is responsible for power management, ECU communication and UDS based diagnostics.

- Algorithms like Field-oriented control, regenerative braking, field-weakening etc. are installed in the MCU platform.

- Generates PWM signal after processing feedback signals from various sensors.

- It is a motor controller for electric vehicles (two and three wheelers), capable of driving motors of considerable wattage

- Custom-designed hardware board that also ensures the correct delivery of power to the Motor

- Contains the pre-driver & the Power MOSFETs

- Responsible for providing the right switching patterns for the Power MOSFET

- Configurable daughter board to support higher motor power rating

- This platform can be integrated with our ready-to-deploy and reusable software stacks (UDS, J1939, OBD and others), as per your requirements.

- Facilitates inter- ECU communication by providing operating parameters of the electric drive train to the external HMI or Other ECUs in the network.

- Implements the UDS (ISO 14229) over CAN BUS diagnostics stack

- Helps in measuring the motor operating parameters

- This Motor Control solution can be integrated with motors like BLDC and PMSM (surface and interior), and AC Induction Motors (single phase and three phase) as per the requirements of the corresponding EVs

- The Motor & the inverter/power stage are tightly coupled elements

Powered with Futuristic Technology and Features of EV Motor Control

Can drive EV motors of considerable wattage

Integrated Field Oriented Control (FOC) algorithm and field weakening feature, to ensure the best dynamic performance of motor

Design & Development is compliant with ISO 26262 Standard for Functional Safety

Motor Control Application has been developed using Model Based Development

Speed control, torque control and Field weakening features to achieve higher speed

Provide motor control solutions across different types of electric motors such as BLDC, PMSM, Reluctance motors and induction motors..

UDS (14229) based diagnostics

Optimization & Tuning of the FOC algorithm using Plant Model Simulation in MATLAB/SIMULINK

Regenerative Braking achieved by voltage boost using Software Algorithm with the help of inverter and motor setup

Technology Architecture of Our Electric Vehicle Motor Control Platform

- The motor control solution consists of the communication, diagnostics and FOC including features like regenerative braking and power management capabilities.

- MCU generates PWM signals that are fed to inverter that runs the electric motors such as BLDC, PMSM and Reluctance motors.

- We can develop motor control solution compliant to ISO 26262 standard as per project’s safety-criticality.

Product Engineering Services for Motor Control Solution Development

Hardware and Software Development Services

- Support for design and development of customized hardware platform

- Ready-to-integrate Field-Oriented Control (FOC) algorithm

- Motor Control System development

- ISO 26262 compliant motor control solution development

- Motor Control System equipped with Regenerative Braking feature

- Supports both sensor-less and sensor-powered commutation for BLDC and PMSM Motor control

- Equipped with Classical Trapezoidal Control methodology

Porting and Integration Services

- Support for porting of the software solution to the hardware platform of customer's choice

- BSW (HAL and low-level device drivers) Development and Integration

- Ready-to-integrate Libaray of Communication and Diagnostics Stacks (UDS, CAN, DoIP, J1939 and OBD2)

- Integration of the Flash Bootloader with the motor control solution

Model Based Development

- Model driven approach for FOC development, by leveraging expertise in Matlab and Simulink

- In order to ensure time & cost savings during Bench Testing, we optimize tuning by testing the FOC algorithm using Plant Model Simulation. This is done to achieve the desired speed-torque characteristics

- Cruise control feature using embedded code to regulate speed

- Reusable models that can be customized as per the target platform

- Expertise in SIMScape tool for Plant Model Simulation

- Support for ML, SIL and HIL testing services

- Expertise in Polyspace tool for static code analysis

Motor Controller for Electric Vehicle - Customer Success Stories

Complex Device Driver Development for AUTOSAR Compliant Powertrain ECU

Embitel successfully addressed an Automotive OEM's challenge of integrating new hardware components into an AUTOSAR 4.0 compliant Powertrain ECU for Electric Vehicles. We developed Complex Device Drivers, configured communication channels, and created APIs for seamless interaction between AUTOSAR layers. The solution, based on AUTOSAR 4.0, included comprehensive documentation and was adaptable to multiple hardware variants. Tools like TI microcontroller platform and Vector CANoe were employed in the successful implementation.

Hardware & Software Development of DC-to-DC Convertor for Solar Battery Charger for Electric Vehicles

Our expert teams developed a comprehensive solution for an automotive after-market organization's ambitious solar energy project. The DC-DC converter ECU, designed for passenger vehicles, efficiently harnesses energy from solar panels.

Embitel's expertise in software, hardware, and platform development, coupled with ready-to-integrate LIN stack, ensured project success within a tight timeframe.

Development of Motor Controller for Electric Vehicles and an Application Layer (using MATLAB), for a BLDC Motor

We excelled in developing a Brushless DC (BLDC) EV motor controller solution for a leading Electric Motor supplier. Leveraging MATLAB's Model-Based Development and SimScape, the team simulated and fine-tuned motor parameters efficiently.

Their expertise in reducing hardware components, integrating software layers, and deploying ready-to-use protocols ensured a successful project, meeting speed-torque requirements.

4) Development of Electric Vehicle Platform ECU with Focus on EV Motor Control Applications

Our experts at Embitel successfully developed a customizable Electric Vehicle (EV) Platform Electronic Control Unit (ECU) with a focus on motor control applications. The ASIL C compliant ECU, designed using MATLAB and Simulink, offers flexibility for EV conversion kits.

The project's timely delivery reduced time-to-market and development costs, ensuring a positive impact on EV manufacturing.

5) Development of ASIL B Compliant Electric Vehicle MCU Platform Software

Embitel achieved success in developing an ASIL B compliant Electric Vehicle Microcontroller Unit (MCU) platform software, revolutionizing the EV system. With a focus on superior user experience, our solution included platform software, diagnostics, bootloader, and ISO26262 ASIL B compliant documentation.

Timely delivery reduced time-to-market, enhancing competitiveness for our customer.

Video Explaining Motor Control System- The Brain Behind Electric Motors

Embitel’s Ready-to-deploy Motor Control Solution for Electric Vehicles

Click HereRelated Posts: Learn More About Motor Controller for Electric Vehicles

FAQs Regarding Motor Controller for Electric Vehicles

Ans. Our platform for motor controller for electric vehicle is completely customizable, configurable and ready-to-deploy solution for your Electric Vehicle Applications.

We have designed a suite of Base Software, that consist of the Hardware Abstraction Layer (HAL) and Low-Level drivers (LLD). This Base Software can be customized for integration with your Application layer, helping you save substantial development time and cost (approximately 6-8 months).

As an additional value-add, a critical software module of the Application layer, which is Field Oriented Control (FOC) algorithm, has also been implemented and can be readily integrated with your system.

Depending on the project’s requirements, we can also partner for the development of other modules like regenerative braking, speed and torque limiting and so on, for the application layer.

For an organization, that plans to develop a prototype of motor control ECU for electric vehicles, this configurable platform is an ideal solution.

Ans: The design and development of this motor controller for electric vehicle, adheres to the guidelines of the ISO 26262 Standard for Functional Safety in Automotive.

We have a dedicated team of Functional Safety Consultants and Engineers. This team has in-depth knowledge of the ISO 26262 standard and has also delivered successful Consulting and Implementation projects for our Global Automotive Customers.

We will also extend all the necessary support; in order to help you achieved the compliance for the required ASIL value, for your EV project.

Ans: In order to minimize the bench testing and tuning efforts in the FOC algorithm, we tune it using Plant Model simulation.

Here, we simulate the actual operating environment of the Electric Motor and the Motor Controller Solution for FOC algorithm optimization.

Our Model Based Development team has expertise of more than 13 years in the Automotive Domain. They partner with our EV Team to help our customers save time & cost during Bench Testing.

Ans: Regenerative Braking is a must-have feature w.r.t an Electric Vehicle motor control system. Our platform too, is equipped with the software algorithm that does the voltage boosting necessary to achieve regenerative braking.

Ans: Our Motor controller solution for Electric Vehicles is built on TI C2000 Delfino family of microcontroller, which is an automotive grade MCU.

In order to help you develop the system on a different microcontroller, we will provide support for the necessary customization of the low-level drivers, of our base software module. The existing Hardware Abstraction Layer designed by our team can be reused completely.

Ans: Our motor controller for electric vehicle is designed to drive different types of motors including BLDC, PMSM, and AC Induction motors.

For all the applications in which these motors are integrated in an Electric Vehicle, our motor control system can be leveraged to demonstrate your PoC.

(Specifications – Our motor controller ECU can drive 2 PMSM motors of 170 Watt and 5kW each, and 1 BLDC motor of 1 kW)

One of the most widely implemented use-case is the Drivetrain of Electric Vehicles (both two-wheelers and cars).

Other auxiliary motor applications can also be built using this platform.

Electronic Power Steering is another use case of our motor controller driven BLDC motor. It may not be specific to Electric Two-Wheelers, but every electric car/truck (four-wheeler or higher) will need power-steering.

Ans: We have implemented certain diagnostics and fault-handling capabilities in the motor control system ECU.

Following algorithms for diagnostics are implemented in the application layer:

- Overload Protection

- Over-voltage, Over-current protection

- Fault detection and logging

- Temperature Monitoring

Ans. Yes, we do provide support for integration in the production environment for the motor controller ECU.

We have a team of hardware engineers who can take care of the implementation of the application, HAL and LLD in the vehicle phase.

We can carry out this activity on-site or support from our premise.

- LLD and HAL implementation skills,

- ISO 26262 Functional Safety expertise

- Model Based Development and AUTOSAR expertise

- FOC algorithm development

- Bootloader development (Re-usable stack)

- Hardware development skills w.r.t motor control system