About the Customer:

Our customer is a leading Battery Management System (BMS) solution provider catering to high-voltage EV platforms across the automotive and energy storage sectors. Their focus lies in creating robust, scalable systems aligned with ISO26262 safety standards.

Business Challenges:

How do you make something that already works—safer, smarter, and scalable across voltage ranges from 300V to 1000V?

That was the challenge laid before us. The customer needed an advanced, safety-compliant Battery Management System platform that could scale across diverse EV applications. Not only did it have to meet stringent ASIL-D safety requirements, but it also had to support high-voltage operations, integrate complex diagnostics, and enable reliable communication interfaces.

More critically, they needed a partner who could build an integrated hardware + software platform, offering flexibility, future-proof scalability, and ease of integration with their existing toolchain and ecosystem.

Embitel’s Solution:

We began with a principle that defines every Embitel solution — build for today’s reliability and tomorrow’s scalability.

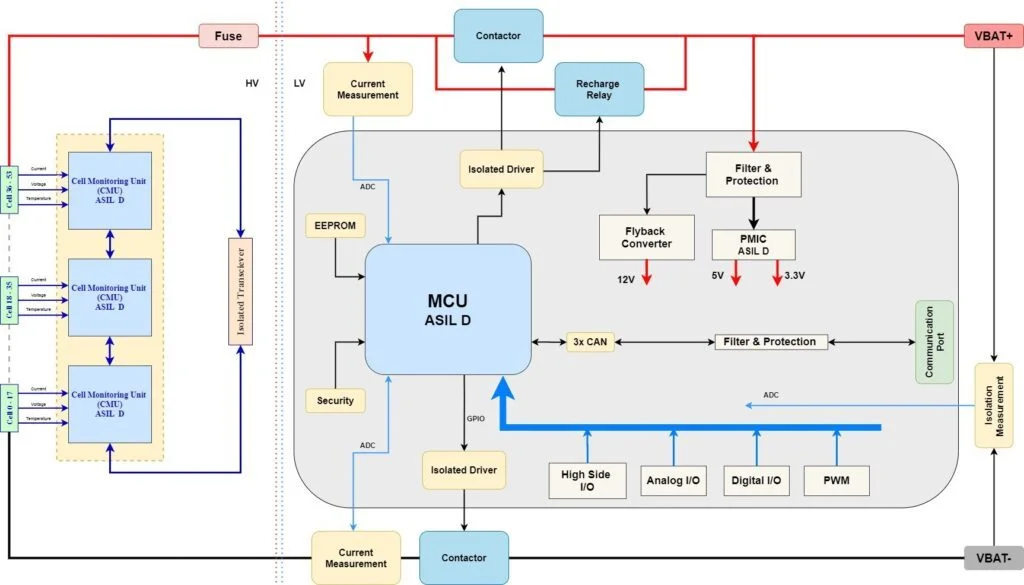

Our engineering team developed a fully integrated ASIL-D Compliant Platform for Battery Management Systems using the NXP S32K3 series MCU, a choice aligned with performance, safety, and support for complex automotive systems.

To address the diverse and demanding requirements of modern EV battery packs, the solution was architected to support a wide operating voltage range, making it adaptable across multiple EV architectures—from two-wheelers to commercial vehicles. This was achieved through a modular battery packing system, where each Cell Monitoring Unit (CMU) could connect up to 18 cells—currently the highest supported in the market—allowing for high-resolution monitoring and flexible configurations.

One of the key technical challenges was ensuring accurate and real-time computation of Voltage, Current, and Temperature (VIT) data across this wide voltage span. Our team implemented robust data acquisition and processing algorithms to extract high-fidelity VIT insights, enabling predictive diagnostics and improved battery lifecycle management.

To meet ASIL-D functional safety requirements, the platform was designed with redundancy, diagnostics, and safety mechanisms across both hardware and software layers. We also ensured seamless integration with existing AUTOSAR stacks and performed rigorous validation to align with ISO 26262 standards.

The development was executed by a cross-functional team of embedded software engineers, safety architects, and system integration experts, ensuring a streamlined path from prototyping to production readiness.

Here’s how we structured the solution:

- Custom Hardware Design built around the NXP S32K3 series controller, tailored to meet the high-voltage range requirements (300V to 1000V).

- Software Stack Development that included:

- Low-Level Drivers (LLD)

- Hardware Abstraction Layer (HAL)

- Communication & Diagnostics Stack

- Diagnostic Application Layer compliant with UDS ISO14229 and ISO-TP

- Self-Diagnostics, DAL, and modular components

- Communication Architecture: Implemented CAN-FD drivers, interface layers, and robust network management for real-time data exchange.

- Signal Interface Layer: Ensured seamless access to Base Software (BSW) signals from the BMS application layer.

- Safety First: Developed in accordance with ISO26262 standards for ASIL-D, one of the highest safety integrity levels in automotive systems.

Why this matters: This platform is not just compliant—it’s adaptable. It empowers EV manufacturers to configure and deploy BMS applications with greater agility and assurance.

Embitel Impact:

With the ASIL-D compliant platform in place, the customer’s journey moved from uncertainty to confidence.

- Goodbye to redesign bottlenecks

- Accelerated launch timelines

- Seamless integration

- Safety first, always.

- Unified architecture across EV segments

Gone were the bottlenecks of redesigning the BMS for every new voltage range. What they now had was a modular, scalable platform—like a versatile toolkit—that adapted to both 300V and 1000V systems with equal precision.

Launch timelines that earlier stretched over quarters were now compressed into months, thanks to the platform’s reusable architecture and built-in diagnostics.

Our solution plugged directly into the customer’s existing systems—no painful overhauls, no costly disruptions. Where they once wrestled with fragmented toolchains and compatibility issues, integration became seamless.

Most importantly, the platform stood as a safety-first foundation, aligning perfectly with ISO26262 ASIL-D standards. That meant fewer compliance hurdles, fewer test cycles, and a far greater sense of assurance for their OEM partners.

Today, the customer’s BMS platform powers a spectrum of EVs—from nimble two-wheelers to robust commercial vehicles—each one backed by the same core architecture, same safety philosophy, and the same engineering depth.

It wasn’t just a platform. It was a turning point in how the customer approached BMS development.

Tools and Technologies:

- NXP S32K3 Series MCU

- CodeBeamer (for requirements traceability and lifecycle management)

- ISO26262 – ASIL-D development process

- CANoe (for simulation and validation)

- Polyspace & Tessy (for static analysis and unit testing)

- Embitel’s UDS & CAN Stack solutions