Predictive Maintenance solutions

are manifestations of artificial intelligence, IoT sensors and data science, working in tandem, to optimise the monitoring and maintenance of assets. The assets can be field-deployed IoT devices like solar panels or the parts of an automobile. Most of these assets do not experience sudden breakdown that impedes their functionality. The breakdown of an asset takes time and usually there are multiple warning signals along the way. However, the early warning signs may not come into the notice of the human operator/administrator/driver. This is where predictive maintenance solutions can be beneficial. Such solutions include monitoring technologies that enable:

- Collection of real-time asset data

- Processing of data using machine learning algorithms

- Release of warnings/alerts to the administrator in case of any abnormalities

This allows the administrator/driver to schedule the maintenance of the asset/vehicle part and make repairs even before the failure happens. Predictive maintenance in Industrial IoT helps in reducing unplanned asset downtime and boosts the efficiency of the plant.

Our Predictive and Preventive Maintenance Solution Expertise

In Embitel’s IoT implementation journey of more than 16 years, our IoT team has custom-designed and developed industrial, enterprise and automotive predictive maintenance solutions for customers across India, USA and Europe.

- Industry 4.0 – Solar Energy tracking system, Industrial drive controls

- Enterprise – Enterprise Battery Management Systems (BMS)

- Automotive – Predictive Maintenance (PdM) for vehicle parts

The business benefits that can be derived from our IoT predictive maintenance solutions include:

- Higher asset availability

- Improved work-force productivity

- Optimized energy consumption

- Lower operational costs

- A fool-proof asset management solution at your disposal

Development Services for Cloud Based Predictive Maintenance Solutions

Our Predictive Monitoring, Analytics and SCADA solutions are custom-designed for Asset Management, based on your unique business requirements. All our PdM solutions are designed based on the Internet of Things (IoT) Technology Stack. Listed below are our services pertaining to IoT Predictive Maintenance to help our partners achieve a winning RoI:

- We assist in 24/7 predictive monitoring of your field-deployed industrial/enterprise assets or vehicle parts with the help of a well-designed network of IoT sensors. This helps in foreseeing equipment failures and instances of unplanned downtimes.

- Based on your Asset Management requirements, the monitoring activities and collection of data can be configured as time-based or trigger-based (occurs when a specific event takes place).

- We help in Dataset preparation by refining the collected data. Data filtering ensures that only the relevant set of data is used for further processing.

- With integrated advanced Artificial Intelligence (AI) data analytics tools, enable your Industrial/Enterprise/Automotive Asset maintenance owner to make more accurate and intelligent decisions.

- These AI tools are used to gain insights from large volumes of IoT sensor data, which are crucial to make critical Predictive Maintenance (PdM) decisions.

- As discussed above, the occurrence of a defect or failure may not be sudden. The failure might have been caused due to changes in operating conditions or the state of an asset over a period of time.

- Our Predictive Monitoring solutions use historic data including error logs, failed as well as successful outcomes, and warnings associated with the equipment – such as data records.

- Our Predictive Maintenance (PdM) solution analyses & processes these data records leveraging Machine Learning (ML) techniques. This helps in detecting any anomalous equipment behaviour and its possible failure based on data insights.

- Real-time Industrial IoT or Connected Vehicle data is represented in a visual and graphical format for an enhanced end-user experience.

- With its operator-centric Human Machine Interface (HMI), our predictive maintenance dashboard is designed to enable accurate and faster decision-making.

- Our Industrial IoT interface can also be integrated with touch, voice and gesture-based controls as per your business requirements.

- We help you identify the right cloud solution for the expected workload.

- This way, you can benefit from the agility and synchronisation benefits of hyper scale clouds.

- Improved performance and security are guaranteed with our multi-cloud and hybrid IT services.

Expertise in IoT Tools and Technologies

- Message Queuing Telemetry Transport (MQTT): Regarded as a very versatile and lightweight protocol, MQTT is ideal for environments that allow optimal bandwidth usage. MQTT protocol has minimal code footprint and can run on any type of operating systems.

- NarrowBand IoT (NB-IoT): Designed for applications that require the transmission of small chunks of data over longer periods of time, NB-IoT technology consumes less power, is easy to deploy, offers extended long range coverage and is very reliable and secure.

- Open Platform Communications (OPC): Open Platform Communications or OPC is one of the most widely used protocols for the reliable and safe exchange of data. OPC is a great value addition to an IoT system as it can facilitate safe streaming of data to desired destinations such as a cloud app or a third-party app. Some of the data types captured in OPC are:

- Real time parameter data

- Historical Data

- Alarm and alerts

- Commands

IoT Predictive Maintenance Customer Success Story

Find out how we are partnering with industry leaders to create intelligent, fool-proof industrial maintenance systems using Predictive Maintenance (PdM):

What are the Main Components of Predictive Maintenance Process?

Here are the primary components of our predictive maintenance solutions:

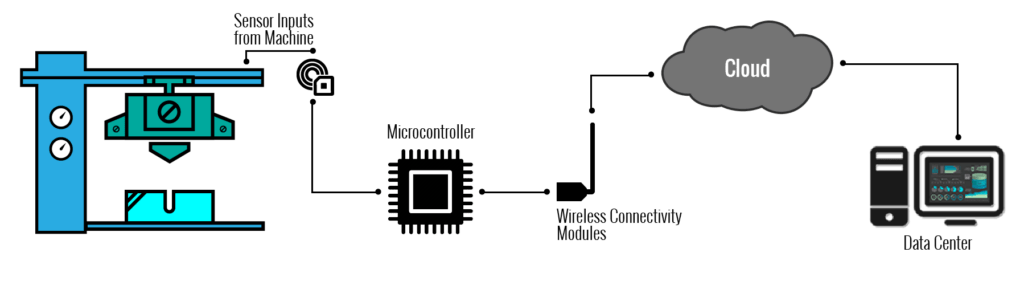

- Sensor Network for Data Collection: A powerful network of IoT sensor nodes is integrated with the assets to constantly monitor their condition. These IoT sensors collect real time data regarding current health of the assets. The collected data is compared with the pre-configured threshold values to detect or predict malfunctions.

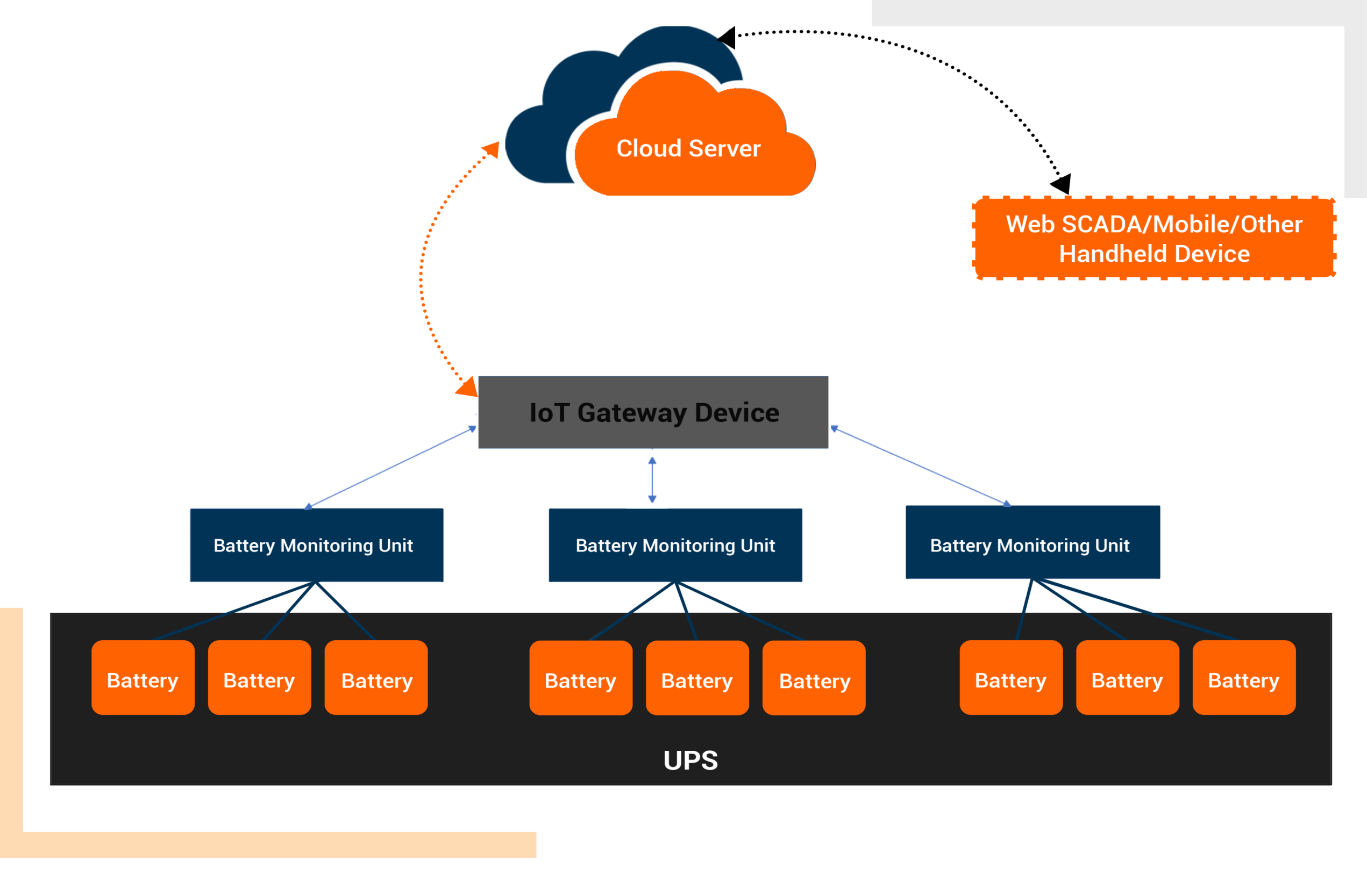

- IoT Gateway Hardware and Software: Microcontroller Hardware board and software design of the IoT Gateway can be custom-made as per the project requirements. The IoT gateway acts as a communication bridge between the IoT sensor nodes and cloud back-end.

- Machine Learning for Predictive Analysis: Raw data from sensors is converted into actionable insights at the IoT Cloud.

- The raw data is filtered to identify relevant information.

- Depending on the project requirements, predictive maintenance algorithms (Machine Learning, Deep Learning, etc.) can be integrated with the Cloud Application. The data is processed and analysed using Machine Learning models and AI tools (based on project requirements), to accurately predict equipment failure.

- The Cloud backend also hosts databases and an interface is designed to manage integrated third party systems.

- Mobile and/or Web Interface: With an operator-centric HMI/UI, the mobile app and web dashboard act as the central control unit for managing the assets. Data is made available in real-time and user-role management, report generation and other plugin integrations can be customized as per the requirements.

IoT Predictive Maintenance – Knowledge Bytes

Knowledge bytes

What is the role of NarrowBand IoT (NBIoT) in enabling Predictive Maintenance of enterprise & industrial assets?

NarrowBand IoT or NB-IoT is one of the prominent mobile Internet of Things Technologies that offers a cost-effective & low power wide area connectivity.

Of late, Narrow Band IoT has found extensive application in industrial automation solutions, especially for predictive monitoring and Industrial Asset Management.

The following are some of the salient features offered by Narrow Band IoT technology.

- Higher penetration power: NB-IoT can be used to connect IoT sensors with factory equipment located in deep pockets, underground levels and other inaccessible places.

- Flexible: NB-IoT is based on Mobile wireless technology that offers more flexibility and reduced deployment cost as compared to a wired connection.

- Optimized for low Power consumption: NB-IoT is a 3GPP-standardised low-power wide area technology.

- Optimized for small data rate: NB-IoT technology has an optimised data transfer rate making it suitable for applications that require reliable transfer of small, intermittent blocks of data.

- Secure and reliable: It supports a host of security features.

What is a predictive maintenance solution?

Predictive Maintenance involves techniques to pre-determine an equipment fault or potential problem, that could over a period of time reduce the efficiency or cause damage to assets.

A Predictive maintenance solution leverages the data, aggregated by a number of IoT sensors, and performs an in-depth data analysis to predict any anomaly in the functioning of the critical equipment.

One of the main advantages of the Predictive maintenance model is that it performs non-interference monitoring and maintenance of the equipment. This minimizes the machine/ production downtimes, which are otherwise one of the major contributors of high operational costs

What are the three types of predictive maintenance?

There are various types of predictive maintenance solutions. Here are three broad categories:

- Preventive maintenance – Such systems continuously monitor the assets and try to prevent the possibility of equipment failure. Past history of failures is considered, and based on that, the likelihood and time of the next occurrence is predicted. Timely measures are then taken to mitigate such an event.

- Risk-based maintenance – Risk-based maintenance handles systems that are highly sensitive to risks. The system analyses and finds the most economical way to minimise risks or prevent them. For instance, if a specific part of a machine is highly prone to damage, a cost-effective process can be employed to protect that part.

- Condition-based maintenance – Such systems completely rely on IoT sensor data. This data reveals the condition of the asset over a period of time. In case there is a decrease in performance of the asset, maintenance activities are performed.

How can predictive maintenance be improved?

Predictive maintenance can be improved by continuously monitoring the solution. It is important to regularly evaluate the performance of the predictive models.

- You could take measures to improve the reliability of data and collection methods.

- You could also fine-tune your machine learning algorithms to improve accuracy of prediction.

The latest trend in predictive maintenance is the smart predictive maintenance solution. Such solutions go one step further and integrate multiple technologies and maintenance approaches. So, you could easily monitor a large network of connected assets with a fair bit of task automation and integration with ERP systems, CMMS, etc.

A few of MBD’s advantages:

- Continuous testing of the software at every stage ensures that it is free from bugs/ errors and is of the highest quality.

- Time-to-market is reduced considerably as code doesn’t have to be written manually.

- MBD makes it easier to design Complex functions, as it requires less iterations.

- Cost of development is reduced.

- Test suites can be reused for different production programs.

Related Blogs: Learn more about Predictive Maintenance Solutions, Future Trends of Industrial Asset Management & more

- Does the Future of Industrial Asset Management Belong to Predictive Maintenance?

- What is Predictive Maintenance (PdM)? Learn How Industrial IoT Enables PdM

- Predictive Maintenance case-studies from Railway, Energy, Oil & Minerals Industries: The Challenges and Benefits

- [Vlog] How Does a Predictive Maintenance (PdM) Solution Work?