Motor Controller for Electric Vehicles – E-Autos, 2 Wheelers and 3 Wheelers

Did you know? Embitel’s customized motor control solutions power diverse electric vehicle powertrains worldwide, supporting motor types like BLDC, PMSM, SRM, and induction motors. Our expertise has accelerated the development of advanced EV platforms, reducing turn-around time for EV programs by up to 40%!

Global Impact: Our motor control solutions have been successfully deployed across 25+ EV projects globally, empowering customers with end-to-end development services, including platform software, diagnostics protocols, and low-level drivers.

Partner with Embitel Technologies to unlock the full potential of your EV program! From bespoke algorithms to tailored hardware integration, we deliver motor control solutions that drive results and innovation.

Product Engineering Services for Motor Control Solution Development

Hardware and Software Development Services

Porting and Integration Services

Model Based Development

Optimized Motor Control Solutions – Powerful, Scalable, and Efficient

Configurable Control

for Dynamic Power

10%

Optimized Energy Recovery

ISO 26262

ASIL-D Compliant

Modular Design

for Easy Adaptation

Scalable

Architecture

Motor Controller for Electric Vehicle - Customer Success Stories

[Demo Video] How our Experts Use FOC Algorithm to Overcome the Speed Error in Motor Control Solutions

Closer Look at Software and Hardware Components of An EV Motor Controller

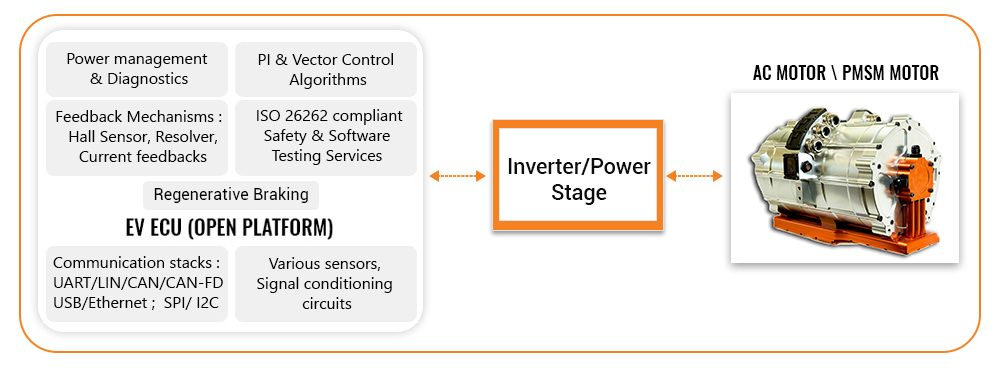

- Microcontroller unit is responsible for power management, ECU communication and UDS based diagnostics.

- Algorithms like Field-oriented control, regenerative braking, field-weakening etc. are installed in the MCU platform.

- Generates PWM signal after processing feedback signals from various sensors.

- It is a motor controller for electric vehicles (two and three wheelers), capable of driving motors of considerable wattage

- Custom-designed hardware board that also ensures the correct delivery of power to the Motor

- Contains the pre-driver & the Power MOSFETs

- Responsible for providing the right switching patterns for the Power MOSFET

- Configurable daughter board to support higher motor power rating

- This platform can be integrated with our ready-to-deploy and reusable software stacks (UDS, J1939, OBD and others), as per your requirements.

- Facilitates inter- ECU communication by providing operating parameters of the electric drive train to the external HMI or Other ECUs in the network.

- Implements the UDS (ISO 14229) over CAN BUS diagnostics stack

- Helps in measuring the motor operating parameters

- This Motor Control solution can be integrated with motors like BLDC and PMSM (surface and interior), and AC Induction Motors (single phase and three phase) as per the requirements of the corresponding EVs

- The Motor & the inverter/power stage are tightly coupled elements

Powered with Futuristic Technology and Features of EV Motor Control

Can drive EV motors of considerable wattage

Integrated Field Oriented Control (FOC) algorithm and field weakening feature, to ensure the best dynamic performance of motor

Design & Development is compliant with ISO 26262 Standard for Functional Safety

Motor Control Application has been developed using Model Based Development

Speed control, torque control and Field weakening features to achieve higher speed

Provide motor control solutions across different types of electric motors such as BLDC, PMSM, Reluctance motors and induction motors..

UDS (14229)based diagnostics

Optimization & Tuning of the FOC algorithm using Plant Model Simulation in MATLAB/SIMULINK

Regenerative Braking achieved by voltage boost using Software Algorithm with the help of inverter and motor setup

Technology Architecture of Our Electric Vehicle Motor Control Platform

- The motor control solution consists of the communication, diagnostics and FOC including features like regenerative braking and power management capabilities.

- MCU generates PWM signals that are fed to inverter that runs the electric motors such as BLDC, PMSM and Reluctance motors.

- We can develop motor control solution compliant to ISO 26262 standard as per project’s safety-criticality.

Video Explaining Motor Control System- The Brain Behind Electric Motors

Embitel’s Ready-to-deploy Motor Control Solution for Electric Vehicles

Related Posts: Learn More About Motor Controller for Electric Vehicles

FAQs Regarding Motor Controller for Electric Vehicles

Ans. Our platform for motor controller for electric vehicle is completely customizable, configurable and ready-to-deploy solution for your Electric Vehicle Applications.

We have designed aQA suite of Base Software, that consist of the Hardware Abstraction Layer (HAL) and Low-Level drivers (LLD). This Base Software can be customized for integration with your Application layer, helping you save substantial development time and cost (approximately 6-8 months).

As an additional value-add, a critical software module of the Application layer, which is Field Oriented Control (FOC) algorithm, has also been implemented and can be readily integrated with your system.

Depending on the project’s requirements, we can also partner for the development of other modules like regenerative braking, speed and torque limiting and so on, for the application layer.

For an organization, that plans to develop a prototype of motor control ECU for electric vehicles, this configurable platform is an ideal solution.

Ans. The design and development of this motor controller for electric vehicle, adheres to the guidelines of the ISO 26262 Standard for Functional Safety in Automotive.

We have a dedicated team of Functional Safety Consultants and Engineers. This team has in-depth knowledge of the ISO 26262 standard and has also delivered successful Consulting and Implementation projects for our Global Automotive Customers.

We will also extend all the necessary support; in order to help you achieved the compliance for the required ASIL value, for your EV project.

Ans. In order to minimize the bench testing and tuning efforts in the FOC algorithm, we tune it using Plant Model simulation.

Here, we simulate the actual operating environment of the Electric Motor and the Motor Controller Solution for FOC algorithm optimization.

Our Model Based Development team has expertise of more than 13 years in the Automotive Domain. They partner with our EV Team to help our customers save time & cost during Bench Testing.

Ans. Our Motor controller solution for Electric Vehicles is built on TI C2000 Delfino family of microcontroller, which is an automotive grade MCU.

In order to help you develop the system on a different microcontroller, we will provide support for the necessary customization of the low-level drivers, of our base software module. The existing Hardware Abstraction Layer designed by our team can be reused completely.

Ans. Our motor controller for electric vehicle is designed to drive different types of motors including BLDC, PMSM, and AC Induction motors.

For all the applications in which these motors are integrated in an Electric Vehicle, our motor control system can be leveraged to demonstrate your PoC.

(Specifications – Our motor controller ECU can drive 2 PMSM motors of 170 Watt and 5kW each, and 1 BLDC motor of 1 kW)

One of the most widely implemented use-case is the Drivetrain of Electric Vehicles (both two-wheelers and cars).

Other auxiliary motor applications can also be built using this platform.

Electronic Power Steering is another use case of our motor controller driven BLDC motor. It may not be specific to Electric Two-Wheelers, but every electric car/truck (four-wheeler or higher) will need power-steering.

Ans. We have implemented certain diagnostics and fault-handling capabilities in the motor control system ECU.

Following algorithms for diagnostics are implemented in the application layer:

- Overload Protection

- Over-voltage, Over-current protection

- Fault detection and logging

- Temperature Monitoring

Ans. Yes, we do provide support for integration in the production environment for the motor controller ECU.

We have a team of hardware engineers who can take care of the implementation of the application, HAL and LLD in the vehicle phase.

We can carry out this activity on-site or support from our premise.

Ans. The skill set of Engineers who have developed the motor control system is as follows:

- LLD and HAL implementation skills,

- ISO 26262 Functional Safety expertise

- Model Based Development and AUTOSAR expertise

- FOC algorithm development

- Bootloader development (Re-usable stack)

- Hardware development skills w.r.t motor control system

Ans. An EV motor controller optimizes energy efficiency by precisely regulating the power supplied to the electric motor, ensuring optimal performance and minimizing energy wastage.

Ans. Motor controllers for Electric Vehicles include safety features such as fault detection, overcurrent protection, and emergency shutdown mechanisms, ensuring compliance with industry standards and enhancing overall vehicle safety.

Ans. Regenerative Braking is a must-have feature w.r.t an Electric Vehicle motor control system. Our platform too, is equipped with the software algorithm that does the voltage boosting necessary to achieve regenerative braking.

Ans. The integration of IoT technology in an EV motor controller enables real-time data exchange, allowing users to monitor and control their vehicle remotely, showcasing the advancement of connectivity features and improving the overall user experience.

Ans. An EV motor controller utilizes sophisticated control algorithms to adapt to various driving conditions and user preferences, providing a seamless and customized driving experience.

Ans. The design of a motor controller for Electric Vehicles incorporates advanced thermal management systems to mitigate overheating issues, ensuring consistent performance and prolonged lifespan.

Ans. The motor controller manages regenerative braking by intelligently converting kinetic energy back into electrical energy, facilitating efficient battery charging and extending the vehicle’s range.

Ans. A motor controller for Electric Vehicles optimizes the performance of the electric drivetrain by precisely controlling the motor’s speed, torque, and direction, resulting in efficient power delivery and enhanced driving dynamics.