Did you know?

The global EV Battery Management System (BMS) market was valued at approximately $1.42 billion in 2021 and is projected to grow at a CAGR of 17.2%, reaching$5.67 billion by 2027?

Efficient BMS are crucial for maintaining battery health, with studies indicating that EV batteries retain about 90% of their capacity after 100,000 km and 87% after 300,000 km, thanks to advanced BMS technologies.

But wait, there’s more! The integration of wireless Battery Management Systems (wBMS) can reduce wiring harnesses by up to 90%, leading to more efficient vehicle designs and reduced manufacturing complexity.

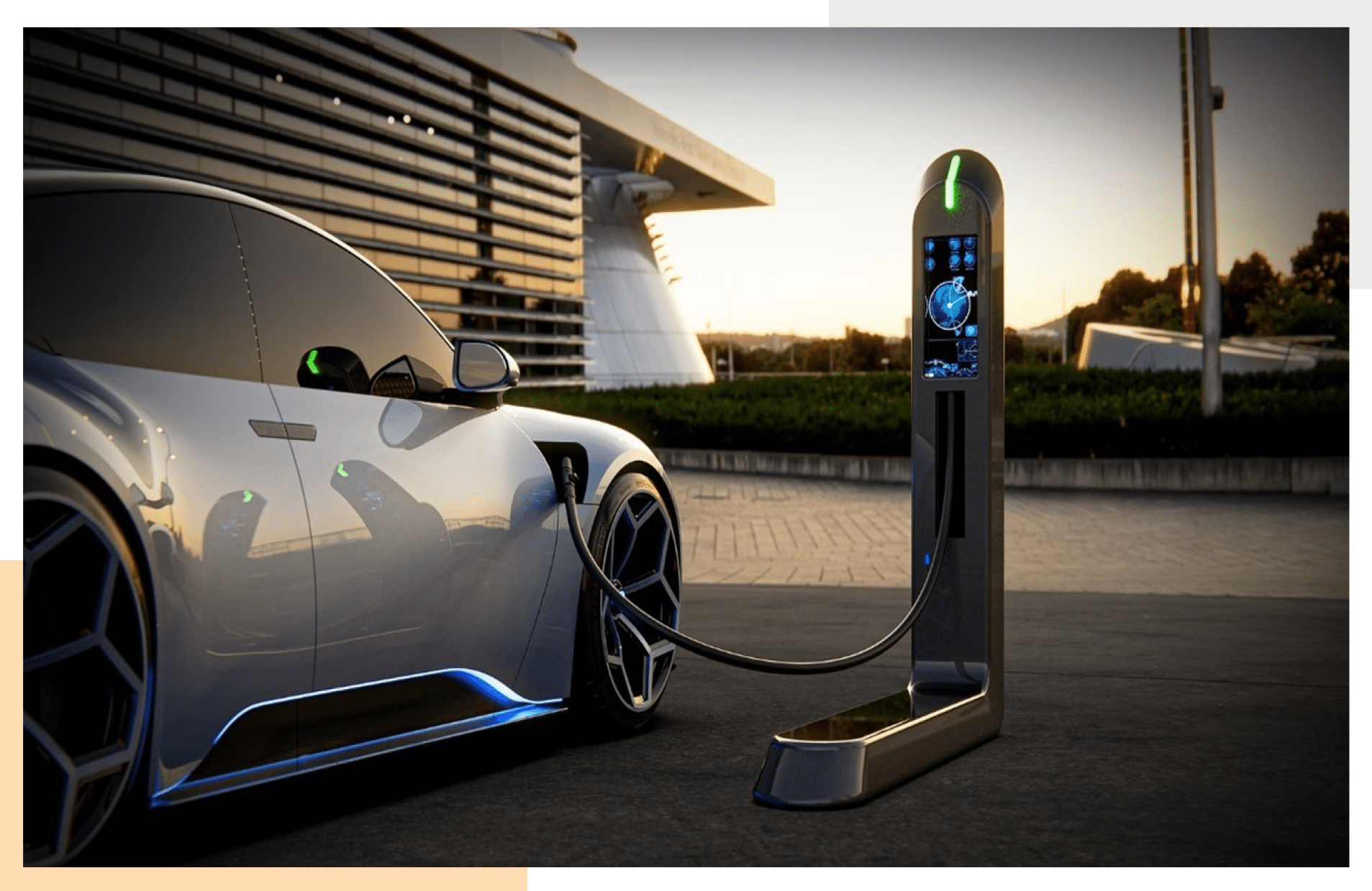

Unlock the full potential of your EV batteries with Embitel’s cutting-edge BMS solutions! Our expertise in developing customizable and robust BMS ensures optimal battery performance, safety, and longer life cycles, empowering you to lead the EV market.

Embitel’s Battery Management System Service Offerings

Voltage and Current Protection

Temperature Monitoring

Cell Monitoring / Balancing

Diagnostics and Relay Control

Optimized Charging and Discharging

Isolated CAN Communication

48+

Certified Employees

62+

Certifications

99.9%

Platform Uptime

4.63 / 5

Customer Satisfaction Score

Customer Success Stories

Interested to know more about our EV services? Get in touch with our consultants and get the details!

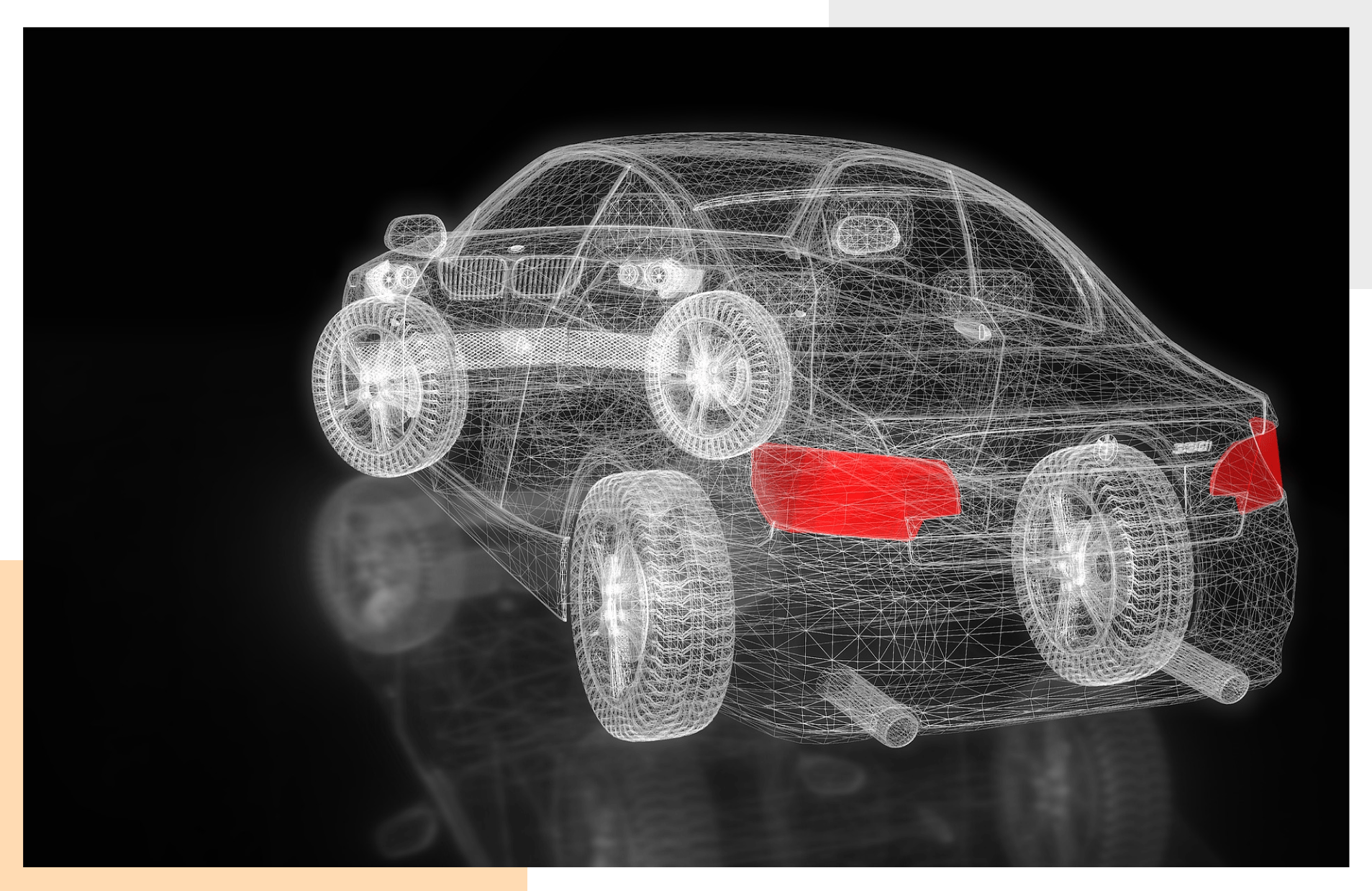

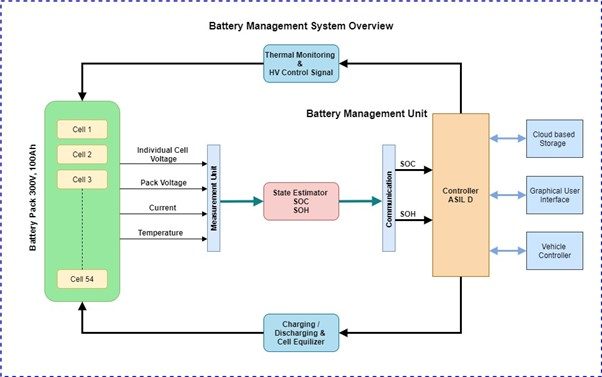

Battery Management System for Electric Vehicles – Basic Architecture and Block Diagram

A smarter, Safer and efficient Battery’s cognitive core – We assist on custom design and developments of Battery Management Systems for all types of EVs (two, three and four wheelers)

Key Functionalities

Smarter, Safer and efficient Battery’s cognitive core

Cell Monitoring

Battery State calculation

Performance optimization

Protection

01

Hardware Features

- Model-based design (MBD)

- Optimized low power consumption mode

- ISO 26262 capable system

- Battery Thermal Management

- Safety and Fault management System

02

Safety Features

- Up to ASIL-D (ISO 26262 functional safety)

- Self-test & redundancy

- Open circuit detection

03

Battery Features

- High frequency sampling

- Battery Standard Portable application IEC 61960

- Daisy Chain and Ring Topology

- Battery Pack Monitoring

- Compatible with LiFePO4

Want Some Technical Insights of our Expertise?

We are Here for It

Hardware

- ASIL-D & AEC qualified components

- Optimized BOM with alternatives

- Customize schematic & PCB layout design

- Signal Integrity, Thermal, EMI/EMC analysis

Software

- ASIL-C Compliant Platform SW Development

- Automotive current sensing and coulomb counting

- Communication: CAN-FD Driver + Interface Layer + Network management

- Diagnostics Layer: UDS ISO14229 and ISOTP

Related Blogs and Articles

- How Advancement in Software Is Propelling the Growth of Electric Vehicles?

- Will Innovations in Battery Management System, Electric Drive & Powertrain Make Electric Vehicles Survive its Recent Comeback?

- Battery Management System for Electric Vehicle: Ensuring Safety and Reliability of Electric Vehicles