Automotive Digital Instrument Cluster

Delivering unique driving experiences through streamlined and timely information display

The connected digital instrument cluster is a technical breakthrough that has fueled massive transformation in automotive dashboards. It provides clear and concise display of vehicle parameters, to the driver, at the right time, to avoid driver distraction and elevate the driving experience altogether.

A digital instrument cluster surpasses the functionalities of its analog counterpart and differentiates automotive product lines in the competitive marketplace.

Embitel partners with global OEMs and Tier 1 Suppliers to design and develop cutting-edge digital instrument clusters for modern connected vehicles.

Key Features of Our Custom-Designed Digital Instrument Cluster

Collaborate with us to develop connected cluster solutions that are:

Dynamic

Dynamically change the information displayed based on vehicle or driving conditions.

Sophisticated

Display only the most relevant information in the least intrusive manner to avoid driver distraction.

Scalable

Easily add more functionality to the digital instrument cluster by upgrading software.

Personalized

Implement custom design considerations to incorporate your unique business ideas and brand voice.

Digital Instrument Cluster HMI – Selected Project Achievement Story

We accomplished quick start-up of an automotive digital instrument cluster HMI module so that the images were updated on the screen within 10 milliseconds!

Connected Cluster Design and Development Services

Development of Complete Digital Cockpit Solution

- A fully connected and secure system that combines multiple experiences on a single platform

- Device virtualization technology to separate the operating system (OS) of the digital instrument cluster from the infotainment system OS

- ISO 26262 compliant solution development for failure safety

- Advanced Driver Assistance Systems (ADAS)

- Integration of Driver monitoring app for driver behavior assessment, voice assistance and other AI capabilities

- Vehicle Infotainment system development

- Integration of Over the Air (OTA) update module

- Heads Up Display (HUD) unit development

- Integration of Telematics module

- Product development considering holistic IoT security principles

Digital Instrument Cluster Hardware Design

- Evaluation of business requirements and selection of microcontroller platform

- Design of hardware schematics

- Hardware testing in compliance to automotive standards and business use cases

- Inclusion of features to facilitate future expansion and upgrades

Vehicle Instrument Cluster Software Design and Development

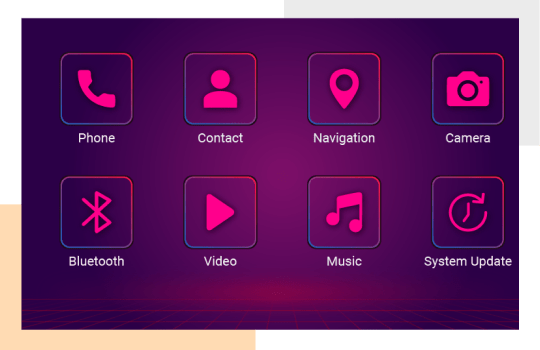

- Assistance for implementing features such as phone and cloud connectivity, navigation, FOTA update module, alerts and warning, etc.

- Development of BSP and middleware software modules

- Development of software components and device drivers

- HMI/UI design and development to suit a wide range of budgets and use cases

Digital Gauge Display Development

- Design and develop a customised HMI module for your digital instrument cluster

- Expertise in user-centric 3D HMI development

- Touch and gesture control features

- Localisation and multilingual support features

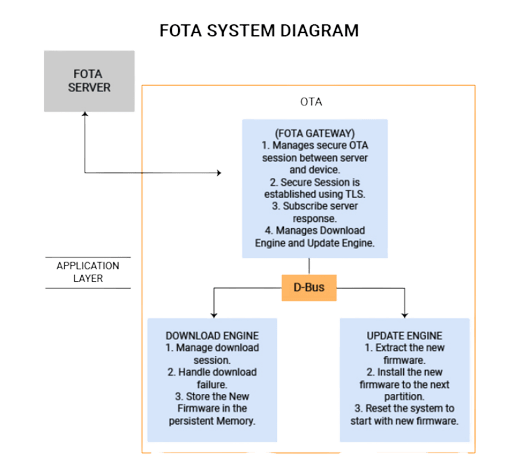

Ready-to-Deploy FOTA Micro Stack for Connected Cluster

Our FOTA micro stack accelerates the development of connected smart clusters. The micro stack facilitates the introduction of new software features or existing firmware update, over the air. Firmware update is orchestrated through the cloud, and it can be scheduled at a specific time. Once the binaries are downloaded from the cloud, the system restarts to install and execute the changes. While end-to-end implementation of an automotive FOTA solution may take 60-70 days, our ready-to-deploy stack enables this feature in 18 days. The FOTA micro stack includes the following modules:

- FOTA Gateway

- Download Engine

- Update Engine

FOTA Micro Stack – Error Handling Features Error handling sequences are initiated when the following events occur:

- The connection with FOTA server is lost

- Discrepancy in firmware version is detected

- There is a download failure

- There is an installation failure

Ready-to-Deploy Bluetooth Micro Stack for Smart Clusters

Our Bluetooth Classic micro stack enables the driver to connect their mobile phone to the vehicle’s smart dashboard. Passcode pairing is performed to establish a safe connection between the phone and the Android based dashboard. On successful pairing, the call logs and contact details are shared with the smart dashboard. The Bluetooth stack has a modular architecture. So, based on the customer’s requirements, specific modules can be chosen and implemented for their project. Various features enabled by the Bluetooth micro stack are as follows:

- Hands-free Calling – This is implemented using the Bluetooth profiles – PBAP (Phone Book Access Profile) and HFP (Hands Free Profile). Alerts for incoming calls and messages are displayed on the smart cluster screen. The user is also able to make outgoing calls from the HMI, and these are routed through the mobile phone. Hardkeys enable the user to make quick calls to important or frequently-used phone numbers.

- Bluetooth Audio – This feature is implemented using A2DP (Advanced Audio Distribution Profile) and AVRCP (Audio/Video remote Control Profile). As soon as Bluetooth pairing is completed, music files from the phone can be displayed on the dashboard screen. Audio playback and pause control is available on the screen.

Smart Cluster Architecture with FOTA and Bluetooth Micro Stacks

The FOTA and Bluetooth micro stacks are available to customers on a one-time licensing fee model. As per this model, the customer jointly owns the IP rights of the software and source code of the stack. They can also deploy the stack across multiple projects.

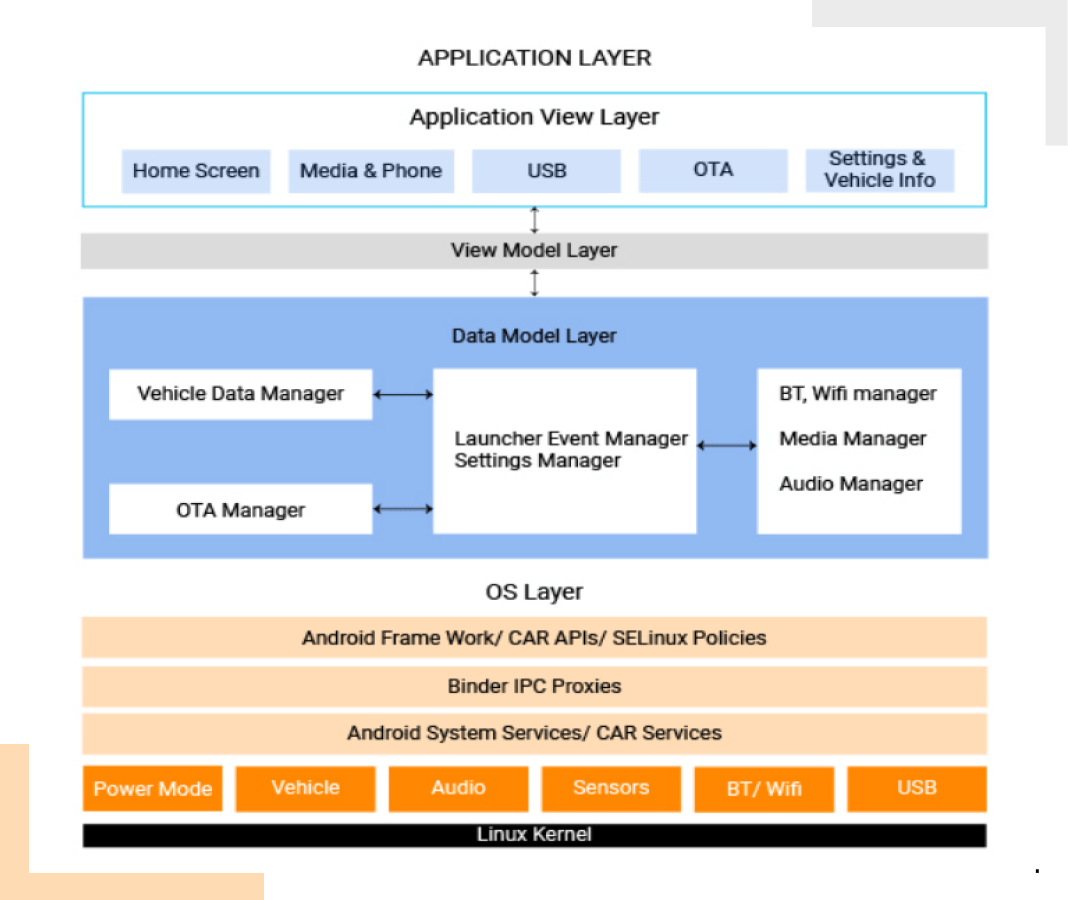

The FOTA and Bluetooth stacks can be integrated with a smart cluster as shown in this architecture diagram.

Connected Instrument Cluster Development - Customer Success Stories

[Video] Why is Digital Instrument Cluster an Ideal Solution for Electric Scooters?

Related Articles

FAQs on Digital Instrument Cluster Development

Ans. The hardware configuration will change based on real-time dependence on OEM defined functionality. For example, in two-wheelers, there is no need to include an advanced audio system as music applications do not have priority in this case.

On the other hand, a good audio system will enhance the dashboard of a car or a truck. While designing the instrument cluster for such vehicles, priority managers are required. The role of the priority manager is to ensure that a specific audio track takes priority over the other when both are scheduled to play at the same time. For example, phone vs music, phone vs navigation guidance, Voice Recognition (VR) vs navigation, etc.

VR is the most important feature in cars, but this is not required in two wheelers. Similarly, HVAC and Rear View Camera (RVC) are other features that need to be incorporated in digital instrument clusters of cars and heavy vehicles.

Ans. It can be different for different System on Chip (SoC). When you select NXP SoC from i.MX 8 family, you will require 1.5 GB RAM for two-wheelers and 2 -2.5 GB RAM for four-wheelers and trucks.

Ans. Yes, this is possible. There are different ways to achieve the digital e-cockpit solution with a single SoC. Please get in touch with our team to understand how this can be done.

Ans. No, it is not mandatory to have a secure OS.

Ans. Android Automotive OS, Linux, AGL – Automotive Grade Linux.

Ans. These are some of the application frameworks we use for this purpose:

- Qt & QML

- Kanzi Studio

- Altia

- Unity

Ans: SVN – Stolen Vehicle Notification

The user can remotely enable this feature from mobile/web, once the stolen vehicle comes online. Once the SVN is received, it is possible to disable few functionalities such as touch and acceleration.

VPN – Vehicle Position Notification

Through this notification, the user will know about the vehicle’s position. Geo fencing can also be used to define VPN.

Ans. No, it is not recommended to update the Android OS over Bluetooth because of footprint.

Ans. Yes, in the past we have worked on a similar project for a leading supplier of automotive electronics products. In that project, we developed a connected digital instrument cluster with the assistance of our Ecosystem Partners, from whom we procured cost-effective LED screens best suited for the project. Connect with us to learn more about our capabilities in this area.

Ans. Yes, we have recently worked on a project in which we integrated a Bluetooth connectivity module with a two-wheeler digital instrument cluster. The primary MCU was on a different module of the cluster. The MCU of our Bluetooth module makes a connection with the primary MCU through UART and reads the fault codes, speed, odometer info, fuel level details, etc. This information is also sent to the mobile application of the rider.

Additionally, the cluster connects to the cloud and transmits vehicle data. This information is processed in the cloud to derive intelligent insights.

Reach out to our team at sales@embitel.com to learn more about this project.

Ans. A digital instrument cluster collects various types of vehicle data from ECUs and sensors spread across the vehicle through communication networks like CAN, LIN, Ethernet, FlexRay, etc. This data is then decoded and converted to a format that can be consumed by the user and displayed on the cluster screen. Some of the sensors that provide data to the digital gauge cluster are engine coolant sensor, fuel sensor, anti-lock braking system (ABS), airbag, oil level sensor, seatbelt, etc.

Ans. Analog instrument clusters have screens with needles that display data by pointing to corresponding numbers on a scale. The movement of the needles directly correspond to the engine fuel variations, vehicle speed changes, etc. These gauges are completely mechanical and are made of small moving parts and gears. Such needles are also susceptible to mechanical vibrations and can wear out quite often.

On the other hand, digital instrument clusters display vehicle data in numbers on a digital screen. Such clusters can perform well under mechanical vibration. They also have good backlighting and the data is easier to read, unlike analog gauges where there can be parallax errors. Digital gauges are powered by high-end microprocessors and software and hence, they provide accurate readings.

Digital gauges are more expensive than analog gauges. However, they do not have to undergo regular calibration and replacement due to wear and tear like analog gauges. Hence, in the long run, they are a more cost-effective and reliable option. This is why auto OEMs are adopting digital gauge clusters in their modern vehicles.

Ans. The instrument cluster is commonly referred to as the dash or dashboard. This is actually a misnomer, as the dash and dashboard are what the driver sees in front of them just behind the steering wheel, while driving. The instrument cluster is a part of the dashboard that contains gauges depicting vehicle and driving conditions.

Ans.

The modern digital instrument clusters have several sophisticated features that enhance driver experience in the vehicle. Listed below are some of these features:

- Customisable displays – High-end digital instrument clusters can allow the driver to personalise the layout and appearance of the displayed information. The driver can configure the style of the gauges, adjust the colour schemes, and also choose what data should be displayed.

- Advanced navigation – Digital gauge clusters have sophisticated navigation systems that accurately provide turn-by-turn (TBT) navigation assistance. They also display real-time traffic updates and points of interest in the locality.

- Augmented Reality (AR) based Head-Up Displays (HUDs) – Some vehicles have HUDs that project important information onto the windshield in an AR display. Crucial information such as driving speed, navigation instructions and safety warnings are directly visible on the windshield. Since the data is displayed in the driver’s line of sight, it minimises driver distraction and facilitates quick action.

- Smartphone connectivity – Most digital instrument clusters allow the user to connect their smartphones via Bluetooth to the cluster. Smartphone integration platforms like Android Auto enables the driver to use phone apps and make/receive phone calls directly from the cluster screen.

- Adaptive information display – The cluster display can change based on the driving mode chosen. For example, if the vehicle is in off-road driving mode at a remote location, the display can show a map of the surroundings to guide the driver.