About the Customer:

We partnered with an automotive Tier-1 supplier with a vision to develop future-ready automotive solutions. Our collaboration with this company spans multiple projects related to solution development, ISO 26262 compliance, verification and validation support, flash bootloader development and more.

Business Challenges:

Our customer was developing an electronic steering adjustment system (Tilt and telescopic). Since the project follows ASPICE standard, development and complete testing of the system also needs to be performed as per ASPICE. Unit Testing, Integration Testing, and Functional testing (System testing) of such a complex solution requires enormous amount of man hours, if performed manually.

- Expertise required for tools like VT system for HIL testing

- ASPICE system level 2 expertise was required

- Expertise in tools for Unit testing, integration testing and static code analysis

To mitigate these challenges and complete the testing as per ASPICE standard, the customer came on-board with us.

Embitel’s Solution:

Phase-wise release of the solution was planned during the discussions with the customer and our development team.

Following aspects were part of the project plan:

- Software design, implementation, and testing

- Hardware design, implementation, and testing

- System design and testing (HIL testing using VT system)

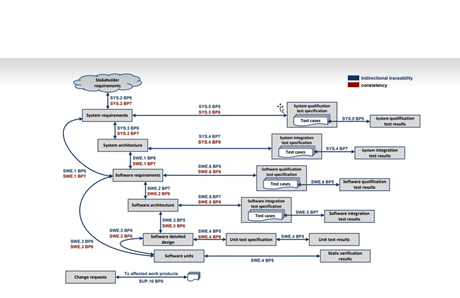

- ASPICE compliance by maintaining bi-direction traceability, so that every point in the report traces back to a requirement

Entire spectrum of testing right from unit testing and integration testing to software qualification testing was covered during the project lifecycle. The testing team was built in a way to include experts of all forms of testing.

Final Deliverables of the Testing Activities:

- Summary test report

- Release report

- Separate document listing issues raised during testing

- Diagnostics and fault testing document (open current, overload current)

We followed the ASPICE v3.1 standard document for planning and executing the test activities.

Embitel Impact:

We automated the functional testing of ECU which resulted in 70-80% of code being tested in the automation mode. Using CAPL scripting, the test cases were automated and the execution of tests took only 4-5 hours. It would have otherwise taken 1-2 weeks for manual testing.

Tools and Technologies:

DOORS tool: DOORS is a requirement management tool. It is used to create test cases based on the requirements.

V Test Studio: V Test Studio is a test authoring tool for embedded systems.

CANoe: It is a software tool for development, test and analysis of automotive ECUs.

CAPL: CAPL scripting is used to automate test case creation and execution.