About the Customer:

Our customer is a Europe based Tier-1 Supplier of Automotive Steering Solutions. They were searching for an experienced Product Engineering partner for Proof-of-Concept development, for one of their ambitious Electronic Power Steering solution.

Business Challenge:

There was a limited time frame for developing the complete hardware and software components of the electronic power steering and also validate it on the test-bench created by the OEM.

On top of that, the system was supposed to be ISO 26262 ASIL-D compliant. This required expertise in creating safety plans and to follow the complete safety lifecycle as mandated by ISO 26262 standard.

Moreover, the need for integration with software stacks like J1939, was also felt to manage the communication with automotive ECU. Since we had a ready-to-deploy J1939 stack solution, we were confident of adding value to this project by reducing the time-to-market.

The customer also evaluated our expertise in motor controller development. By the virtue of our experience and skill-sets, we were on-board for this proof-of-concept development of EPS ECU.

Embitel’s Solution:

After a few rounds of discussion with the customer’s automotive steering and driveline solutions team, it was decided that MPC5643L dual core micro controller will be best suited hardware platform for this project.

Our task was precisely cut-out, which was to develop the complete vehicle ECU hardware and software solution for the EPS.

The first step was to develop the hardware using this microcontroller. Following components were developed and integrated with the system:

- ASIL-D certified MPC5643L dual core micro controller.

- 2 KW NIDEC Motor (Automotive Grade).

- ASIL-D Pre-driver Component– Controls the motor with integrated PWM; Regulates HALL sensors etc.

- Gate Driver IC- Acts as power amplifier for MOSFETS; Also sends error feedback to the ECU in a closed loop system.

- H-Bridge Component– MOSFETs.

- Steering Angle and Toque Sensor– Measures the angle and torque on the steering.

- HALL Sensor Feedback– To measure RPM, Motor Speed etc and send the data to the ECU.

- Temperature Sensors- Measures the temperature and feeds the reading to the ECU. This facilitates shutting down of the motor at high temperature.

- Voltage measurement sensor- Measures the motor voltage and passes the info to the ECU as a feedback.

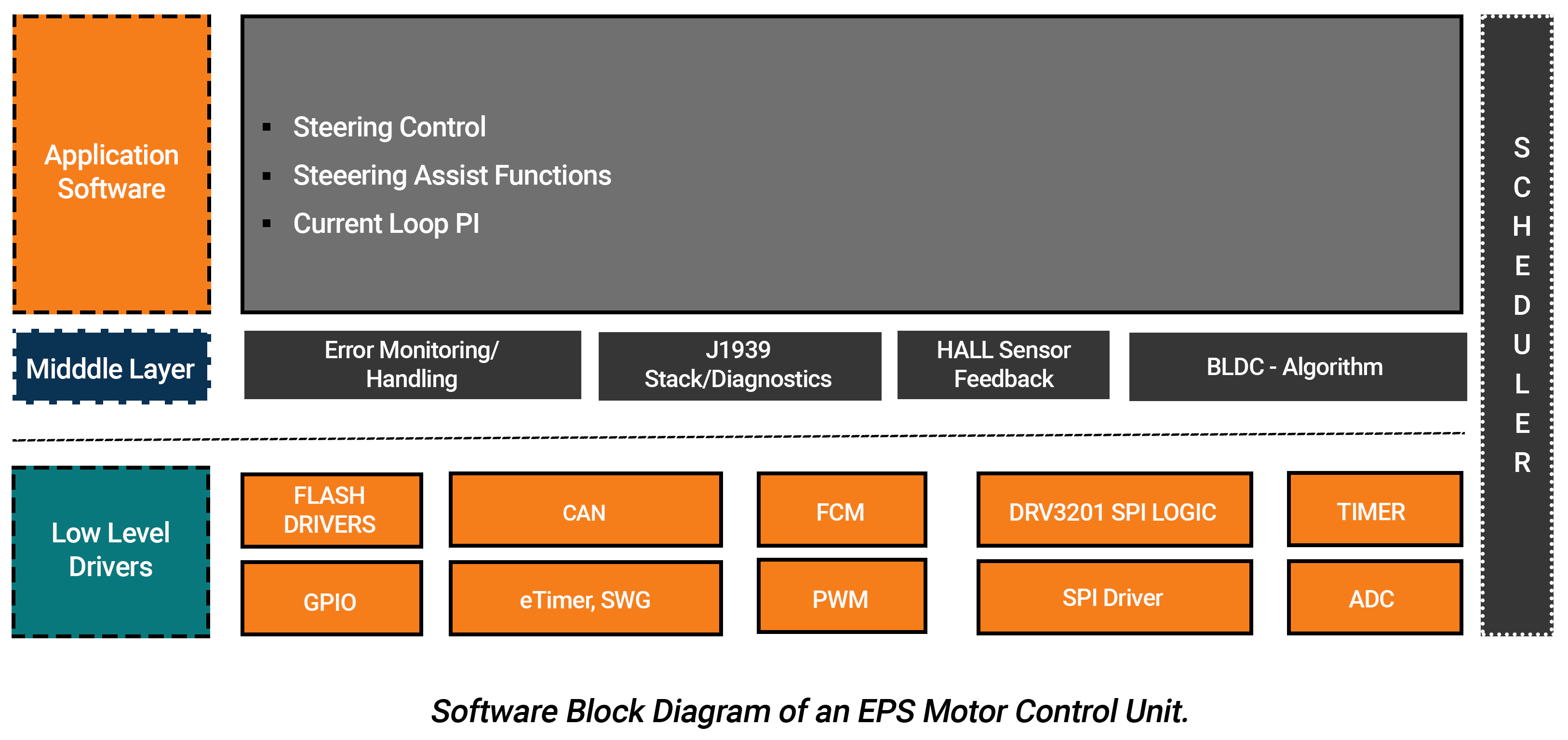

Our team also partnered to develop low-level drivers, hardware abstraction libraries and the application software required for the hardware platform and the peripherals.

We also designed various software algorithms in order to support necessary Motor Control features and functionalities.

Here’s the complete list of software algorithms that were developed:

- Steering Control– Assist factor algorithm; torque sensors value, and angle sensor provided as inputs to the steering assist function, by external hardware. This algorithm also fetches RPM value via CAN message.

- Motor Control– It is an algorithm that sets the motor speed based on the torque. It also interfaces with steering assist functions.

- Signal conditioners– They smoothen the pulse value from the hardware. The sensors will provide ECG like values that need to be conditioned. This is called signal conditioning. The value is given to the motor controller after signal conditioning.

- Sensor Drivers– ADC drivers are required for reading the values from the sensors.

- Actuator Drivers– PWM- used to adjust the motor speed; Gate driver unit drivers.

- J1939 Based Bootloader and Diagnostics: Ready-to-deploy stack for ECU communication and vehicle diagnostics.

- Standard Core- Memory handling, EEPROM, Scheduler.

We tested the software and hardware using various testing tools. We also collaborated with the customer for End-of-Line Testing. We tested all the software and hardware components on the test bench provided by the customer.

Some of the issues faced during this process and how they were rectified:

The major problem that was faced in the test-bench was a jerk in the steer wheel. We were not able to get the desired smoothness.

Based on the parameters, we identified the issue in the assist factor algorithm. Our automotive developers were able to fine-tune the algorithm to adjust the assist factor.

“A safety lifecycle for hardware and software development was running in parallel to ensure that the components are ISO 26262 ASIL-D compliant. A safety manager was assigned for this and was supported by different teams.”

Embitel’s Impact:

We were successful in developing the POC in 3 months- the time period that we were given by the customer. This helped the customer develop a PoC of an ISO 26262 ASIL-D Electronic Power Steering ECU in a short period of time.

We were able to accomplish the task due to the following reasons:

- Our power steering system and software capabilities.

- Ready-to use Bootloader J1939 for diagnostics.

- Team of Motor Control Experts.

Tools and Technologies Used:

- IDE- CodeWarrior.

- Vehicle Spy for CAN Signal Simulation.

- CANOe Analyser.