About the Customer:

The customer, an Indian Subsidiary of one of the Global Pioneers in Renewable Energy generation.

Business challenge:

The customer had earlier partnered with us for the development and implementation of IoT based Solar Tracking System.

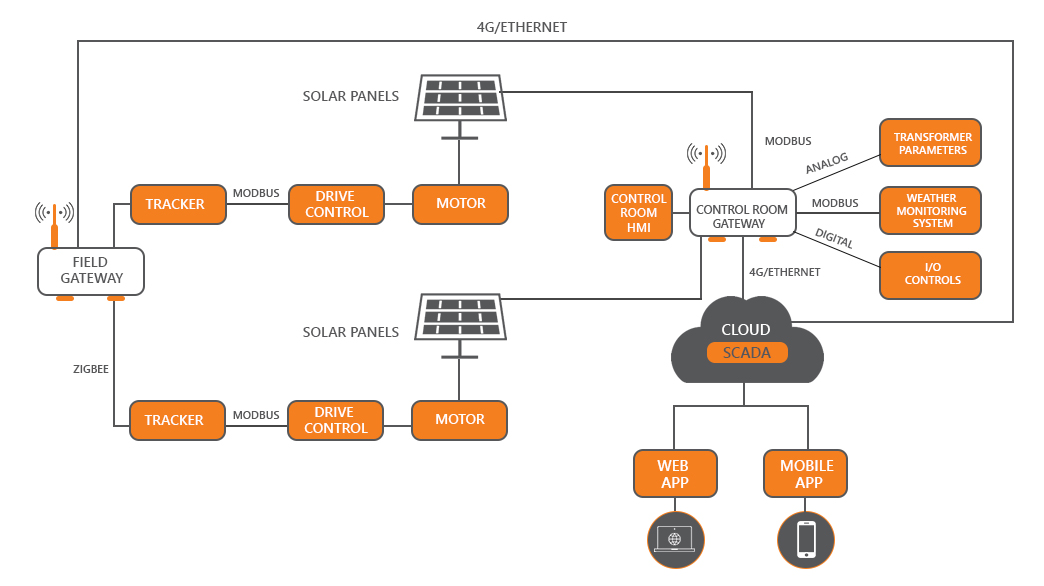

Some of the key components of the high–efficiency Solar Energy Tracking System developed by Embitel included:

- Single Axis Solar Panels and Tracker.

- Custom-built Field Gateway.

- Drive and Motor Control Systems.

- Integration with Off-the-Shelf Control Room Gateway.

- Cloud Based SCADA system for 24/7 monitoring.

This field deployed IoT based Solar Energy Harvesting Solution, designed and developed by Embitel’ s IoT developers, has been instrumental in helping our customer to improve the efficiency of power generation and remote management of their on-field industrial assets.

Also Read: Customer Success Story- IoT Platform Development & SCADA solution for the Solar Tracking System.

The following block diagram gives an overview of the IoT based Solar Energy Harvesting System.

Additionally, the off-the shelf gateway device was designed by deploying multiple control Units or Modules for managing specific tasks. All these lead to an additional BOM cost and increased complexity of the IoT Gateway architecture.

Thus, with the aim of reducing the cost of the Control Room Gateway and simplifying the hardware architecture, customer decided to invest in a custom-built control room gateway device.

After having worked with Embitel for the full-fledged Solar Energy Harvesting Solution, the customer was impressed with Embitel’ s expertise in Product Engineering and Industrial Automation services . Customer had no hesitation in further extending this partnership for the new project.

Embitel Solution:

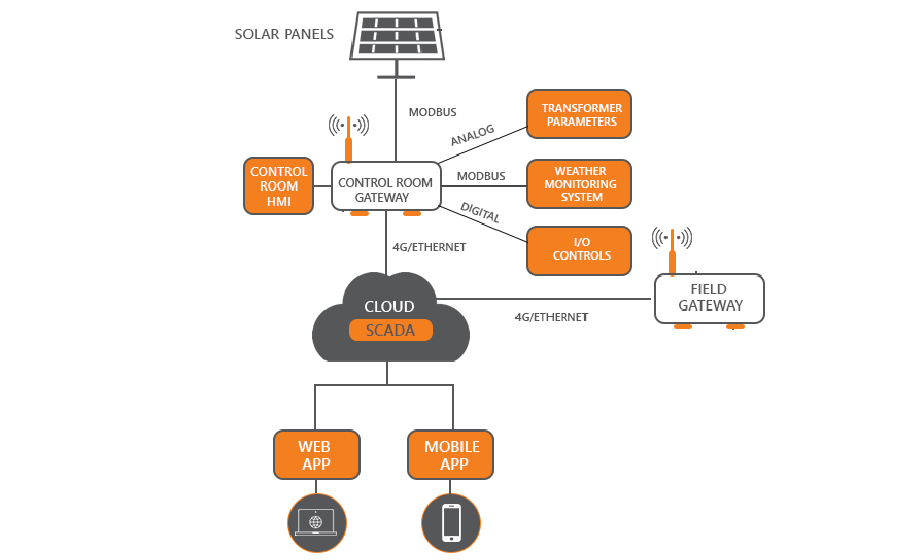

Embitel’ s IoT experts performed a detailed analysis of the functional requirements of the Control Room gateway device.

This analysis revealed that the several components and architecture of the existing Field Gateway, developed by Embitel for the customer, can be re-used for the customization of the Control Room Gateway.

The new Control Room Gateway device basically had to be a scaled-up version of the Field Gateway Device, with additional control features and peripherals.

The re-usability of the existing IoT Gateway hardware and software proved to be a great value-add for this entire project.

Please refer to the following block diagram to get an overview of the Control Gateway Device and various peripherals connected to it.

- Custom Hardware Development Custom hardware modules and peripherals were developed and integrated with the control gateway device to support the following features:

- Input/ output module consisting of 48 inputs and 16 output pins. These I/O are used to monitor system status and to control system features like ALARMs and ALERTs.

- Transformer parameters: It supports remote monitoring of various transformer parameters such as coil winding and oil temperature.

- String Combiner Box: The String combiner box is a device that combines the output of multiple strings of PV modules, and feed the o/p to an inverter. A control board in the string combiner box monitors parameters like voltage, current and communicates the same via Modbus interface. The control room gateway reads these parameters and forwards this information to the SCADA system. In such a setting, the SCADA system will be able to generate alerts about any fault in any of the PV modules.

- Energy Meter: The control Room Gateway reads energy generated at the solar power plant via Modbus from the Energy meter and forwards to the SCADA.

- Weather monitoring system: The control room gateway device also gathers information related to – the speed and direction of wind, ambient temperature and humidity – from a weather monitoring system over Modbus interface.

- Inverter: The inverter converts the DC power generated by the PV panel to AC. The control board in the inverter provides Modbus interface to read inverter parameter. The Control Room gateway reads these parameters and forwards to the SCADA. Control gateway supports both Modbus serial and Modbus TCP/IP and depending on the inverter used, these communication interfaces are configured into the gateway.

- Software Development:Additionally, specific software modules were also created to support Modbus communication , I/O module and analog communication between the Control room gateway device and other systems in the Solar Tracking Solution.

- Customized HMI:

The existing HMI and SCADA systems were redesigned to accommodate additional parameters that the Control room gateway device is monitoring.

Embitel Impact:

The integration of custom developed Control Room gateway device, as a replacement of the off-the-shelf device, helped the customer in reducing the overall cost by significant levels.

Tools and Technologies:

- HyperLynx – Verification of Signal Integrity, Power Integrity, and Thermal Analysis.

- Atmel SAM A5 platform: development of gateway hardware boards.

- QT framework for PC-Application and ATS.

- ModBus over RS-485 and Ethernet.

- Django scripting : SCADA solution development.

- Postgress SQL: SCADA database.