Faster Integration Into Existing HVAC / Comfort ECUs

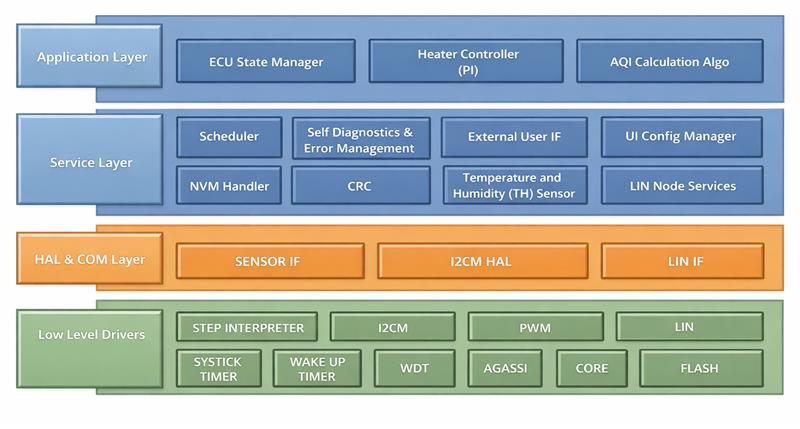

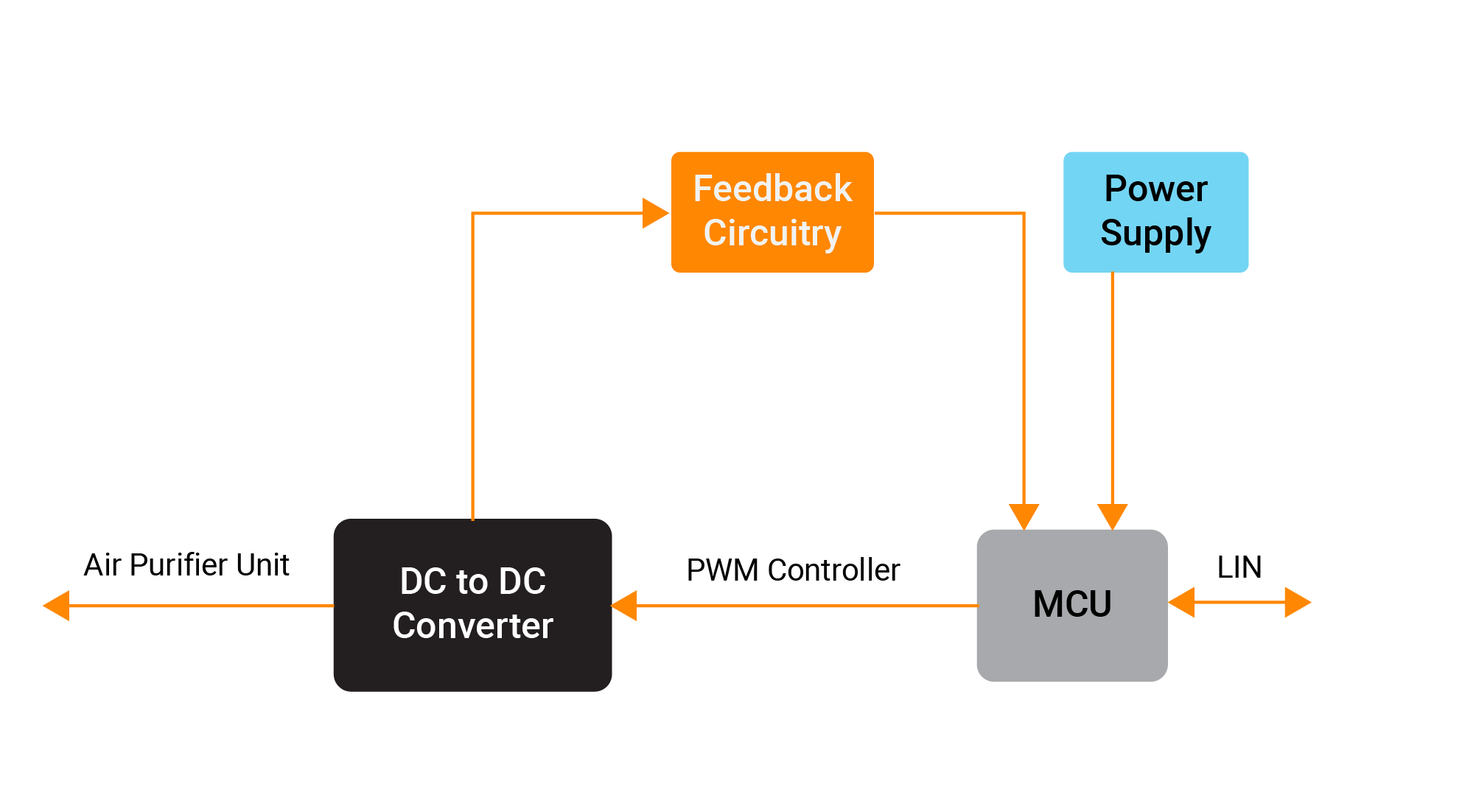

The platform plugs into LIN/I2C/SPI with minimal redesign, reducing integration effort and accelerating bring-up across vehicle programs.

- Automotive & EV▼

- IoT▼

- Digital Solutions▼

- Industries▼

- Technology▼

- Digital Growth Enablers▼

- Commerce & Experience Services▼

- Success Stories▼

- Thought Leadership▼

- Industries

- AI/ML▼

- Company▼

- Careers▼

- Contact Us

- Blog