Enabling Vehicle ECU Built-in Diagnostics Services

OBD2 protocol software is at the core of an automotive ECUs’ built-in self-diagnostic system. It enables diagnostics-based communication with the ECUs such as Engine control unit, transmission control unit, electronic brake modules and more to detect and control ECU failures.

Embitel’s OBD2 Protocol Software

Embitel offers a ready-to-deploy OBD2 protocol software package

based on ISO 15031 standard. With our production-grade OBD2 stack,

you can implement on-board diagnostics communication capabilities

in your automotive ECU development program with reduced

turn-around time.

This OBD2 protocol stack is ideal for supporting on-board

diagnostics functions within all kinds of vehicles.

We offer this OBD2 Protocol stack under a one-time licensing fee

model. This engagement model makes the OBD2 stack highly

beneficial for our customers.

Know more about our OBD2 protocol software business model, features, use-cases, and technical specifications.

Download DoIP factsheet

Striking Features of our OBD2 Protocol Stack

- We offer our industry recognized OBD2 protocol software under a one-time licensing fee model.

- Terms & conditions regarding IP rights and source code ownership are completely transparent and fully aligned with the customer’s requirements and vision.

- UnUnit, Integration and Functional testing of OBD2 protocol including OBD2 APIs, modes and PIDs are performed with relevant tools and test reports are shared with the customer.

- OBD2 protocol software code is compliant to 2012 MISRA C standards.

- Our OBD2 software stack solution can be imple¬mented in an Automotive ECU product as a server, in an External Tool Kit as a client, or in Telematics unit as a slave.

- We have delivered our OBD2 protocol software for Telematics Unit, Fleet Management System, Electronic Logging Device (ELD), etc.

Embitel’s Service Offerings for SAE OBD2 Software and its Integration

OBD2 Protocol Stack Development for Automotive ECU and Tooling Applications

- Development of OBD API which helps in integration of the OBD II stack with the target application and Hardware Layer

- Implementation of OBD modes and PID (Parameter IDs’) as per OBD2 protocol

- OBD2 software integration with automotive ECU application software

- Fault code memory implementation

- Integration of OBD2 Bluetooth Stack

Solution Design for After-Market Automotive Products

- OBD2 software integration, design and development services for after-market automotive products/solutions

- Solution Design for After-Market Automotive Products

- OBD2 software integration, design and development services for after-market automotive products/solutions

- Support for access to vehicle parameters, development of OBD diagnostic interface, data collection and processing

- Development, testing and maintenance support for Telematics, ADAS, Remote Vehicle Diagnostics, Driver Behavior Analysis

- Support for OBD2 Bluetooth and OBD2 Android in solution development

- Support for software development for OBD2 Scanner tooling system

Vehicle Data Collection Solutions for OBD2 protocol

- Consulting workshops to understand the vehicle data collection requirements for OBD2 protocol implementation

- Complete design and functional audit of the existing/legacy system (if any)

- OBD2 software design and development services for data collection from on-road vehicles

OBD2 protocol stack physical layers implementation

- Support for implementation on all automotive physical layers – CAN, K-Line, ISO9141, PWM and VPW (J1850)

- Development of OBD drivers

200+

customers supported since 2010

100+

scalable and reusable Bootloader platforms delivered

30%

quicker time-to-market enabled

95%

lesser development time with PC-based automation tools

Embitel’s Advantage

Industry-wide Recognized

We have integrated OBD2 stack for several production programs across the globe. The extensive experience gives us an edge in the implementation of on-board diagnostics for automotive use-cases.

CMMi Level 3 Certified

As a CMMI level 3 certified organization, we have a robust process model in place. This ensures that the OBD2 stack along with other stacks are reliable, bug-free and efficient.

Configuration & Integration Support

Our OBD2 protocol software is designed to be fully configurable as per project specifications. We provide support for configuration of Tx and Rx messages through CAN IL tool.

Support for After-market Solutions

Development, testing and maintenance support for after-Market Products for Telematics, ADAS, remote vehicle diagnostic applications.

Video Explaining the Need for OBD2 protocol and Off-board Diagnostics

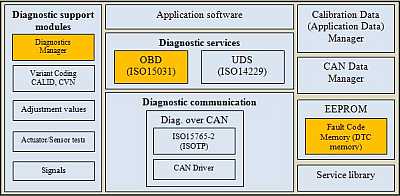

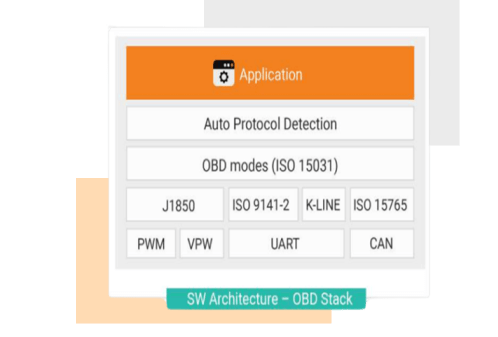

OBD2 Protocol Software Architecture

- ISO 15031 standard complaint OBD services

- ISO 15765 standard complaint OBD over CAN module (CAN TP Layer)

- VPW/PWM drivers to support OBD over J1850

- ISO 14230 complaint UART /K-Line drivers to support OBD over K-Line

- ISO 9141-2 complaint UART drivers to support OBD over ISO9141-2

OBD2 Software Design Implementation: Hardware and Software Expertise

| OBD module | Hardware | Software |

| OBD services | NA | ISO 15031 |

| OBD over CAN |

CAN support in microcontroller CAN transceiver |

ISO15765 (CAN TP layer) |

| OBD over J1850 (VPW/PWM) |

PWM support in microcontroller 1850 transceiver |

PWM driver VPW/PWM driver based on J1850 standard |

| OBD over K-Line |

UART support in microcontroller K-Line/ISO9141 transceiver |

UART driver K-Line driver (based on ISO14230) |

| OBD over ISO9141-2 |

UART support in microcontroller K-Line/ISO9141 transceiver |

UART driver ISO9141-2 driver |

Why Partner with us for OBD2 Protocol Stack Integration Project:

- Leverage our automotive domain expertise and project experience in OBD II protocol stack integration to reduce time-to-market and application development costs

- We are a CMMi Level 3 and ISO 9001:2008 & ISO 27001:2013 certified organization

- Robust project management processes based on EmbiQ – an engagement model. This model is built on three critical pillars – People, Process and Technology.

OBD II Software Stack Business Impact: Customer Success Story

Business Challenge: Design, development and testing of OBD II stack for Engine Control Unit

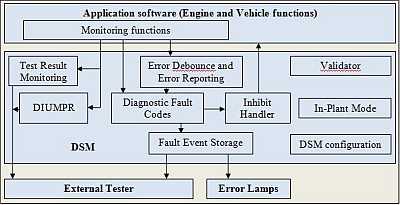

Our team of automotive embedded developers designed following OBD modules after the initial requirement gathering workshop with the automotive customer:

- Diagnostic System Manager (DSM) with Fault Code Memory:DSM modules collects test results reported by the monitoring functions. Current fault states and derived error memory entries are stored in standard form and is readily accessible to the application software and Tester communication.

- OBD Diagnostics Services: This module provides external access to fault code memory and other emission relevant data. A generic OBD scan tool can be connected to the ECU to read emission related data.

For more details about the OBD implementation and tools and technology deployed for this project, please refer to the entire case-study here.