About the Customer:

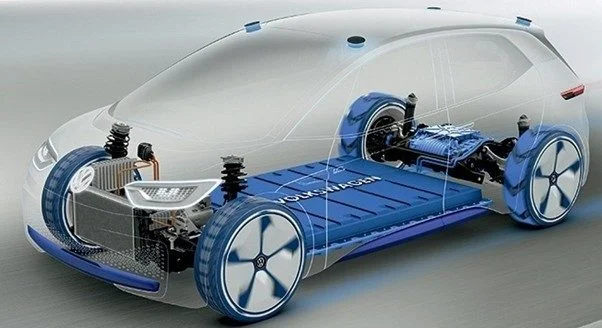

A global Tier-1 automotive supplier, known for its forward-thinking approach to powertrain technologies, was developing a next-generation electric vehicle (EV) control system.

The primary goal was to develop the solution with the highest safety-criticality level (ASIL D). To execute the project, the customer sought an experienced technology partner to design and develop an AUTOSAR based software solution for the new Motor Control Unit (MCU).

Business Challenges:

The automotive industry is undergoing a massive shift towards electrification and software-defined vehicles. For our customer, this transition meant more than just shifting from combustion to electric; it was about embracing a platform approach that supports rapid development, standardization, and compliance with functional safety norms like ISO 26262.

The specific challenge was to develop a Motor Control Unit (MCU) software solution that could:

- Comply with ASIL-D safety requirements

- Be modular and scalable, leveraging the AUTOSAR Classic Platform

- Integrate seamlessly with the existing partially-configured software, which included handwritten bare-metal code

This required not just technical competence, but the ability to debug hardware-level anomalies, interpret legacy code, and deliver a robust and reliable solution.

Embitel’s Solution:

- Understanding the Scope and Strategy

- Building AUTOSAR-Compliant MCAL Modules

- PWM (Pulse Width Modulation) with centre-aligned output

- ADC (Analog to Digital Converter) for precise current measurements

- SPI (Serial Peripheral Interface) and DMA (Direct Memory Access)

- GTM (Generic Timer Module) and other complex configurations

- Complex Device Driver (CDD) Development

- Hardware Debugging and Root Cause Analysis

- A misconfigured isolator IC blocked PWM signal propagation. We discovered and rectified this issue with the hardware team.

- The ADC showed anomalous readings due to a voltage. We traced the root cause to a voltage divider and implemented corrective steps in collaboration with the customer.

- Functional Safety and ISO 26262 Alignment

- Testing and Quality Assurance

- Module-level and system-level testing

- Adherence to ASPICE-aligned process compliance

- Creation of all quality artifacts and engineering documentation as per project milestones

Our engagement began with the understanding that while the existing software stack covered about 70–80% of the requirements, much of it was non-standard and manually written.

We quickly discovered that many modules had to be redeveloped from scratch to achieve full AUTOSAR compliance and meet ASIL D requirements.

Our team, led by experts in embedded systems and functional safety, developed several critical MCAL (Microcontroller Abstraction Layer) modules from the ground up, including:

In each case, configurations were made using AUTOSAR-authorized tooling and verified through rigorous testing.

To meet ultra-low latency requirements of motor control, we designed Complex Device Drivers to bypass certain layers of AUTOSAR and enable direct communication between the application and the MCAL. This was particularly critical for executing Field Oriented Control (FOC) algorithms within strict timing constraints (in microseconds).

We engaged in multiple deep-dive debugging sessions to identify and solve critical hardware issues:

The system was developed for ASIL-D compliance. Our in-house Functional Safety (FuSa) team conducted:

Our team coordinated with the customer’s internal HIL testing group, who took ownership of fault injection testing and stress testing using their proprietary test benches.

Throughout the lifecycle, Embitel supported in:

Embitel Impact:

Despite initial constraints around hardware design and legacy code, Embitel delivered a complete, AUTOSAR-compliant MCU software package in under 6 months. The impact of our solution included:

- Accelerated Development: Reduced customer time-to-market by leveraging our AUTOSAR expertise and in-house reusability assets

- High-Quality Output: Delivered clean, modular code fully owned and controlled by the customer, enabling future reuse across programs

- Hardware Issue Resolution: Identified and helped resolve two critical hardware flaws, improving system reliability and performance

- Customer Confidence: Weekly deliveries and transparent communication built lasting trust with the customer

Tools and Technologies:

- AUTOSAR Stack & Configuration: Vector DaVinci

- Static Code Analysis: Polyspace (MathWorks)

- Requirement Management: PTC Windchill