The growth in the number of cars offering ADAS Level 2 features has been phenomenal. People keeping a close eye on automotive advancements know that many OEMs have ADAS Level 3 testing going on. And it’s only a matter of time when this trickles down to the mass automotive market.

The latest Euro NCAP grading report reveals that OEMs like Volkswagen are bringing high performance ADAS features to the mainstream. Scores such as ‘assistance competence’ and ‘ safety backup’ in the report are clear indicators of giant leaps the entire automotive ecosystem is taking in terms of ADAS advancement.

The development of ADAS demands rigorous Verification and Validation to ensure safety, efficiency, and reliability. In the automotive realm, especially with systems as intricate as ADAS, Verification (Are we building the system right?) and Validation (Are we building the right system?) become paramount.

For instance, for the Adaptive Cruise Control (ACC) feature, Verification ensures the system can adjust speed based on sensor inputs correctly, while Validation guarantees this adjustment indeed enhances driver safety and comfort.

With advancements in technology, the approach to V&V has become multifaceted, involving various simulation techniques and scenario-based testing. Aligning with international standards like ISO 26262 ensures that the V&V processes meet global benchmarks.

A Brief Snapshot of ADAS Verification and Validation Methodologies

In the present scenario, the foundational basis for autonomous driving systems relies on Software in The Loop (SIL) and Hardware in The Loop (HIL) methodologies. The trials for these systems traditionally occur manually, either on isolated test tracks or within the public domain, necessitating a test driver.

But these methods bear imperfections. Primary among them is the challenge of replicating identical road conditions repeatedly. Real-world variables such as traffic density, pedestrian behavior, and environmental factors are almost impossible to recreate with absolute accuracy. Laboratories, with specialized tools, offer a controlled environment where such conditions can be re-enacted, allowing cars to be assessed and certified against standardized procedures.

Numerous research studies outline diverse strategies for testing these advanced safety and autonomous systems. From real-world road traffic evaluations to controlled laboratory experiments, the approaches vary.

A contemporary testing method in labs, termed Vehicle-in-the-loop, primarily concentrates on examining individual components like radar or lidar. The ADAS engineering community’s goal has been to integrate a testing apparatus that can evaluate multiple systems concurrently. However, such a holistic tool remains elusive. Thus, the quest continues: Can we conceive a test setup that impeccably simulates real-world conditions in a laboratory for a comprehensive testing of driver assistance and autonomous systems?

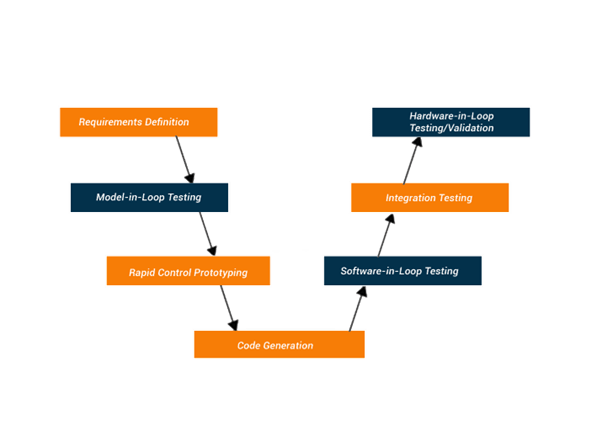

To dissect this, let’s understand the concept of “X-in-the-loop.” Here, “X” symbolizes the entity being tested, and given that testing isn’t a singular event but an iterative process, it’s termed “loop testing.” In the auto sector, numerous facets can undergo loop testing. These methods, in line with system development chronology, are often showcased graphically. Furthermore, it’s crucial to discern between verification and validation. While verification ascertains system compliance with predefined requirements, validation affirms the system’s efficacy in its intended real-world setting.

The journey typically initiates with the Model-in-the-loop (MIL). At this juncture, the system under development exists as a prototype, crafted using modeling software such as MATLAB-Simulink. This high-level abstraction, devoid of intricate implementation specifics, offers an overview of system operation. One can sidestep manual coding by leveraging tools like Simulink Coder or Target Link, generating code directly from this model. The evaluation of this model encompasses feeding it with simulated signals and gauging its reactions.

Following MIL, the focus transitions to Software-in-the-loop (SIL), where the testing entity transitions from a block model to code. The validation here involves administering real-world data inputs. This phase probes the accuracy of the implemented algorithms in a chosen programming language. However, this abstraction bears risks. Variabilities in compilation can induce slight disparities in the machine code, potentially resulting in changed behaviors during execution.

Post-SIL, the trajectory ventures into Hardware-in-the-loop (HIL) testing. Here, the software, embedded in its destined hardware but devoid of its native environment, undergoes scrutiny. Thus, it mandates the simulation of all allied electronic devices. From the perspective of the entity under assessment, the distinction between real and simulated environments blurs.

This HIL testing typifies the automotive industry’s prevalent testing mode. Often, the manufacturer’s remit spans only the device under testing, sans access to collaborating devices. For instance, an Electronic Control Unit (ECU), dedicated to discerning road lanes, might be gauged within a simulated milieu. The inherent limitation here is the absence of real-world synergies—with genuine ECUs, authentic power supplies, and more. This poses the risk of suboptimal performance within authentic environments.

`

Delving Deeper: The Crucial Aspects of ADAS/AD Validation

As we continue our exploration into the intricate world of ADAS and AD validation, several elements come to the forefront. The burgeoning complexity of these systems demands novel approaches to validation that are not only efficient but also extremely reliable.

- Virtual Validation: The Key to Managing Complexity

- The Importance of Real-World Testing

- Scenarios are Central to ADAS Testing

- The Significance of Models

- The Intensive Task of Model Validation

- Sensor Stimulation: Bridging the Gap Between Virtual and Real

As ADAS and AD systems become more sophisticated, traditional testing methods can fall short in covering all possible scenarios. This is where virtual validation steps in.

Virtual validation involves the use of advanced simulations to test ADAS and AD systems in a virtual environment. This allows for a vast number of scenarios to be tested quickly and repeatedly, ensuring thorough validation without the constraints of physical testing.

Instead of physically testing a car’s response to a pedestrian suddenly stepping onto the road in various weather conditions, virtual validation can simulate these scenarios, saving time and resources.

Despite the advantages of virtual validation, real-world testing remains indispensable.

There’s a distinction between a ‘digital twin’ (a virtual representation of the ADAS/AD system) and its ‘real twin’ (the actual physical system). While simulations can come close, they cannot perfectly replicate the unpredictability of real-world conditions.

Factors like tire wear, slight misalignments in sensors, or unpredictable human behavior can introduce nuances that might not be fully captured in a simulation.

At the heart of ADAS/AD testing lies scenarios—predefined situations that the system might encounter.

These scenarios are sourced from multiple areas. They can arise from initial system requirements or analysis, data captured from real-world driving, or even synthetic data created to test edge cases.

Scenarios might include a car navigating through a construction zone, reacting to an ambulance approaching from behind, or handling a situation with a cyclist making an unexpected turn.

Models, often used in virtual validations, play a pivotal role in ADAS/AD testing.

It’s crucial to adapt generic models to specific situations. This adaptation, known as model parametrization, ensures that the simulated scenarios closely mirror potential real-world events. However, creating these models is not a one-size-fits-all task.

A generic model for vehicle behavior might need parameter adjustments to reflect a specific vehicle’s weight, acceleration capabilities, and braking system for accurate simulations. Model parameterization refers to the process of adjusting the parameters of a simulation model to ensure that it accurately represents the real-world system it’s meant to mimic.

This process is essential because while generic models can provide a foundational representation of systems or scenarios, the specifics often vary based on the particular system, environment, or situation at hand.

Also, different vehicles or systems may have distinct specifications and behaviors. Parameterizing allows models to be tailored to these unique specifications, ensuring that each system is tested under conditions relevant to its design.

Constructing a model is just the beginning. Validating it—ensuring it behaves as expected and accurately represents reality—is equally, if not more, crucial.

Significant effort goes into this phase, verifying that the model’s responses in simulations align with expected outcomes in real-world conditions. Any discrepancies can lead to refining the model or adjusting parameters.

If a model inaccurately predicts the stopping distance of a car on a wet road, it will need recalibration to ensure safety in real-world conditions.

One of the innovative methods in ADAS/AD validation is sensor stimulation.

This approach involves simulating the inputs to a vehicle’s sensors in a controlled environment, enabling tests that are close to real-world scenarios but without the associated risks. By feeding synthetic data directly to the sensors, we can test how the system would react in actual driving situations.

In a laboratory setup, a car’s radar might be fed data simulating another vehicle’s approach at high speed, allowing testers to assess the ADAS system’s response without any real vehicles involved.

What are the Common Challenges in ADAS Verification and Validation

Testing and validating Advanced Driver Assistance Systems (ADAS) is a monumental task. As ADAS technology continues to evolve, the complexity of challenges faced by engineers and developers grows. Below are some of the predominant challenges in ADAS testing:

- Complexity of Automated Vehicles

- Interaction with the Environment

- The Vastness of Possible Scenarios

- Rarity of Critical Scenarios

- Sensor Limitations

- Inadequacy of Solely Road Testing

- Necessity of Virtual Testing

- Challenges with AI Validation

Automated vehicles can be aptly described as the epitome of cyber-physical systems. They incorporate intricate hardware and software components that need to interact seamlessly in real-time. This integration is vital for decision-making and maneuver execution based on vast and continuously changing environmental data. Ensuring the harmonious interplay between these components is a formidable challenge.

Unlike many other systems, an automated vehicle doesn’t operate in isolation. It continuously interacts with its environment, which includes other vehicles, pedestrians, infrastructure, and various unpredictable elements. Replicating this dynamic and often unpredictable interaction in testing scenarios is incredibly challenging.

There’s virtually an infinite number of driving scenarios that an ADAS-equipped vehicle might encounter. From a pedestrian suddenly stepping onto the road in a busy city to a fallen tree on a secluded country road, the variations are immense. Simulating and testing for every potential scenario is practically impossible.

While there are countless possible scenarios, many critical situations that test the ADAS capabilities to their limits occur very rarely. These “edge cases” might include, for example, a child chasing a ball onto a highway or a multi-vehicle pile-up in foggy conditions. Identifying and adequately testing for these rare but crucial scenarios is a significant challenge.

ADAS heavily relies on sensors like cameras, radars, and LIDAR. However, these sensors can be less effective or even rendered non-functional in adverse weather conditions such as fog, heavy rain, snow, or even direct sunlight. Ensuring ADAS functionalities remain robust and reliable in these conditions is a pressing concern.

Road testing, while invaluable, cannot cover the breadth and depth of scenarios an ADAS might face. It’s also time-consuming, resource-intensive, and potentially dangerous for edge-case testing.

Given the limitations of real-world testing, virtual or simulated testing becomes indispensable. It allows for the rapid replication of varied scenarios, especially those rare edge cases. However, ensuring the virtual environment accurately mimics real-world conditions is a challenge in itself.

ADAS systems often incorporate artificial intelligence (AI) and machine learning algorithms to enhance their decision-making capabilities. Validating these AI models is complex due to their inherent nature: they continuously learn and evolve. Traditional validation methods may not be applicable, necessitating the development of novel validation techniques tailored to AI.

Conclusion

The journey towards fully autonomous vehicles is paved with technological challenges. Ensuring the safety and reliability of ADAS through rigorous testing is paramount. While the hurdles are many, the advancements in simulation technologies, AI, and collaborative efforts in the automotive industry continue to push the boundaries, inching closer to realizing the dream of safe autonomous driving.