In the automotive testing lab, the engineers may sometimes think of ECU validation as a box-ticking exercise. You run the predefined test cases, get your pass/fail results, and move on. That mindset worked when ECUs were deterministic, when every input had a predictable, rule-based output.

Those days are over.

Modern automotive embedded systems are equipped with machine learning models, decision logic, and adaptive control strategies.

Take lane keeping for example. The ECU responsible for this function does far more than follow preset thresholds. It reads lane curvature from imperfect camera data, compares that with radar inputs, and decides how to steer when the road markings are faded or when glare impacts the view.

These are situations that cannot be validated by a handful of repeatable test cases. Testing this kind of intelligence with static scenarios is like evaluating a racing driver by making them drive the same empty track lap repeatedly. You learn nothing about how they handle traffic, sudden weather changes, or an unexpected obstacle.

What Does AI Agent Powered Testing Bring to the Table?

We have all heard of AI agents by now. These agents can perceive their environment, make decisions, and take actions without human intervention. A good example is a digital assistant that manages schedules, adjusts plans when meetings run late, and keeps tasks on track without being told.

In the context of automotive ECU validation, these AI agents can act as virtual drivers, traffic participants, or environmental elements within simulation and test setups. They can introduce unpredictable conditions, adapt to system responses, and explore scenarios that go beyond pre-defined test cases. This makes it possible to evaluate how the ECU performs in complex, changing situations before the system ever reaches the road.

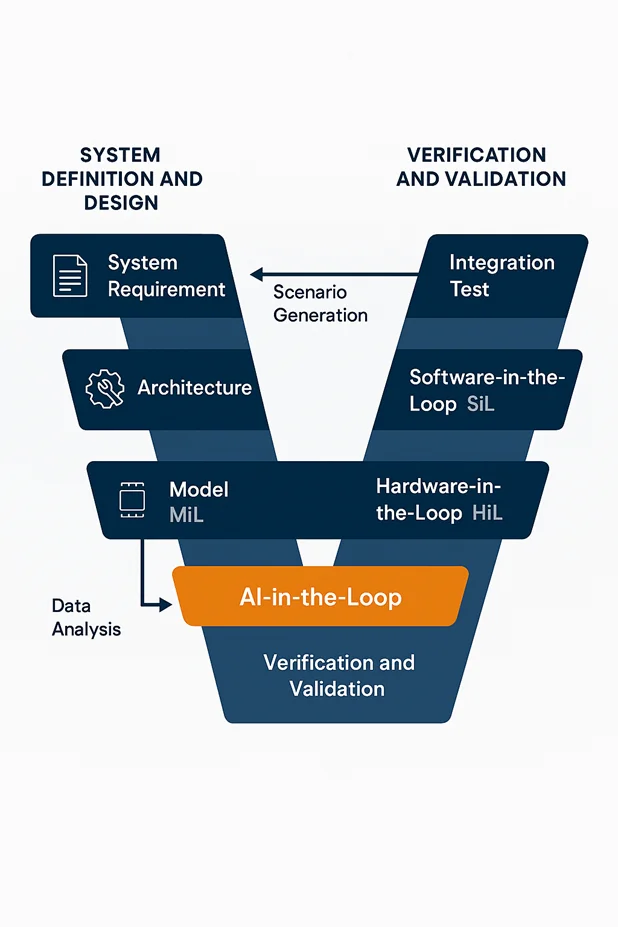

AI-in-the-loop testing embeds such intelligent AI agents directly into the test setup, whether it’s Model-in-the-Loop (MiL), Software-in-the-Loop (SiL), or Hardware-in-the-Loop (HiL).

These agents can:

- Simulate complex environments: Generating dynamic traffic, weather, and road conditions that change in real time.

- Act as adaptive adversaries: Deliberately finding weaknesses by stressing the system with unusual or borderline inputs.

- Accelerate coverage: Automatically exploring input spaces beyond what human test designers could anticipate.

This shift turns validation from confirming expected behaviour into discovering unknown failure modes.

Applications of AI-in-the-Loop Testing in Automotive ECU Validation

Artificial Intelligence is being used in multiple ways within automotive validation.

The first approach focuses on how we challenge the system under test by creating sensor-accurate, highly dynamic virtual worlds that can replicate real road conditions and even create new ones.

The second focuses on how we learn from those challenges by making test data analysis faster, more intelligent, and more targeted.

Together, these approaches not only improve test coverage but also help validation teams uncover problems earlier in the development cycle, when they are cheaper and easier to fix.

Let’s explore them further:

- Sensor Realistic Scenario Generation

- Reproduce varied road geometries, traffic flows, and intersections

- Introduce environmental challenges such as heavy rain, fog, glare, or snow

- Simulate sensor degradation such as lens dirt or partial blockage

- Include AI agents acting as unpredictable road users, cutting in suddenly, hesitating at intersections, or making erratic lane changes

- Automated Test Data Analysis

- Data from simulations and Hardware-in-the-Loop tests is automatically organized and indexed

- Anomalies, performance drops, and unusual patterns are flagged without manual filtering

- Engineers can query the system in plain language, for example “Show me all braking delays over 250 milliseconds in wet road conditions”

- Insights from one set of tests can guide the design of the next, creating a self-improving validation loop

Modern ECUs, especially those in advanced driver assistance systems and autonomous systems, depend heavily on sensor inputs to perceive their surroundings. To validate them properly, engineers need more than static datasets. They need environments that respond dynamically to the ECU’s actions.

AI powered testing enables this by creating high-fidelity 3-D simulations that stream realistic radar, lidar, and camera data in real time. These virtual environments can:

The benefit is not just realism but adaptability. When the ECU reacts, the virtual world reacts back. This allows engineers to see how the system handles evolving and unscripted scenarios that real drivers face every day.

The other major use case focuses on what happens after testing. A single Hardware-in-the-Loop test campaign can generate gigabytes of logs, images, and performance metrics. Manually reviewing this data is slow, repetitive, and prone to human oversight.

With AI driven analysis, the process changes dramatically:

The result is faster turnaround between testing and design adjustments, higher quality insights, and fewer hidden issues making it past the lab stage.

Benefits of AI Powered Testing for Automotive ECU Validation

| Benefit | Description |

| Greater realism in testing | AI in the Loop creates environments that react to ECU decisions. Road users behave unpredictably, weather and lighting change during the test, and sensor inputs include imperfections like dirt or partial blockages. |

| Discovery of hidden edge cases | AI generated test scenarios work outside predefined lists, revealing rare traffic patterns, unusual sensor faults, and combined challenges that traditional scripts may miss. |

| Continuous improvement through feedback loops | Insights from AI generated tests feed back into scenario creation, allowing targeted stress testing of conditions that cause performance issues. |

| Faster turnaround from test to insight | AI tools quickly process large datasets, flag anomalies, and identify trends, reducing the time between test execution and corrective action. |

| Reduced development cost and safety risk | Early detection of flaws reduces reliance on costly physical prototypes and lowers the risk of safety issues appearing late in production. |

| Support for compliance and standards | AI-in-the-Loop testing aligns with ISO 26262, ISO 21448, and ISO SAE 21434, while providing detailed logs and traceability for audits and certifications. |

How AI-in-the-Loop Fits into Existing ECU Validation Workflows

AI based testing is not a replacement for traditional automotive validation methods. Instead, it strengthens Model-in-the-Loop (MiL), Software-in-the-Loop (SiL), and Hardware-in-the-Loop (HiL) setups by adding adaptability and intelligence to each stage.

- Model-in-the-Loop (MiL)

- Early in the development phase, engineers validate control algorithms using mathematical models of the system.

- AI agents can interact with these models, introducing varied and unpredictable inputs to test control logic under a wider range of conditions.

- This helps detect design flaws before any code is written for the ECU.

- Software-in-the-Loop (SiL)

- Once software is available, it is tested in a virtual environment that simulates the ECU and its connected systems.

- AI-in-the-Loop can create dynamic test scenarios that respond to software behaviour, revealing potential performance bottlenecks or unexpected interactions.

- Hardware-in-the-Loop (HiL)

- In this stage, the real ECU hardware is connected to a simulation that mimics the rest of the vehicle.

- AI agents can act as virtual drivers, pedestrians, or other traffic participants, creating conditions that test the ECU’s ability to make decisions in real time.

- This approach allows engineers to see how the actual hardware responds to unpredictable situations before deploying it in a physical vehicle.

- Closed Loop Between Stages

- Insights gained at one stage can guide testing at the next.

- For example, an edge case found in MiL can be recreated in HiL to see how the hardware reacts, and then further refined for future SiL runs.

AI implementation Roadmap for Validation Teams

Proactive validation teams have already started deploying AI agents in the ECU validation workflow. The most common application is using localized AI models in generation of test cases from the requirements and even generation of test reports. But that is barely scratching the surface.

As we have already discussed, there is a lot more to AI in testing than test case generation. However, to fully utilize AI for automotive testing, a clear roadmap is required for the validation teams.

Here’s a generic roadmap that the teams can follow. It goes without saying that teams can modify this, basis their unique requirements.

Phase 1 – Assessment and Planning (1–2 months) Objective: Understand current validation workflows and identify where AI can create value. Actions:

- Map existing MiL, SiL, and HiL workflows.

- Identify pain points in scenario generation, test execution, and data analysis.

- Assess data availability and quality for AI-driven tools.

- Define success metrics (e.g., reduced test cycle time, increased coverage).

Deliverables:

- Gap analysis report

- AI adoption plan with priority areas

Phase 2 – Infrastructure Readiness (2–3 months) Objective: Build the technical foundation for AI integration.Actions:

- Set up high-fidelity simulation environments (3D road, weather, and traffic modeling).

- Establish a centralized test data repository with secure access.

- Integrate APIs to connect simulation tools with AI modules.

- Ensure compliance with ISO 26262, ISO 21448, and ISO SAE 21434 data handling requirements.

Deliverables:

- Simulation and data management infrastructure

- AI-integration-ready test benches

Phase 3 – Pilot AI-in-the-Loop Integration (3–4 months) Objective: Test AI in controlled validation workflows before full rollout.Actions:

- Develop AI agents for scenario generation in MiL/SiL/HiL.

- Train models to introduce edge cases and adapt to ECU responses.

- Implement AI-driven data analysis tools to detect anomalies automatically.

- Run pilot projects on selected ECU functions (e.g., ADAS perception, driver monitoring).

Deliverables:

- Pilot project report with performance metrics

- Refined AI models for specific use cases

Phase 4 – Scaling and Process Integration (4–6 months) Objective: Expand AI-in-the-Loop across all validation stages.Actions:

- Extend AI agents to cover multiple ECU domains (powertrain, infotainment system, safety systems).

- Automate regression testing with AI-generated dynamic scenarios.

- Standardize AI-driven data analysis workflows across teams.

- Link insights from data analysis to design feedback loops.

Deliverables:

- AI-in-the-Loop integrated into core validation processes

- Updated validation SOPs including AI use

Phase 5 – Continuous Optimization (Ongoing)

Objective: Keep AI systems adaptive, relevant, and compliant.

Actions:

- Continuously train AI agents with new road and failure data.

- Monitor AI performance against predefined KPIs.

- Implement governance for explainability, audit trails, and compliance.

- Explore reinforcement learning for self-improving validation agents.

Conclusion

AI in testing is an evolving concept, much like AI itself. As automotive systems grow in complexity, traditional validation approaches alone cannot keep pace with the unpredictability of real-world conditions. AI-in-the-Loop offers validation teams the ability to create dynamic, intelligent, and adaptive testing environments. This would help them uncover issues earlier, improve coverage, and accelerate development cycles.

The future of validation will not just include AI, it will run on it.