The emergence of gas stations has a fair bit of history- evolving from depots with hand-operated suction pumps to facilities with motorized fuel dispensers.

At its current stage, the entire operation of refueling an Internal Combustion (IC) engine car is not very complicated when compared to an Electric Vehicle. It merely requires the oil to be transferred from the underground gasoline tanks to the vehicle’s fuel tank with the help of a hose. There are no compatibility issues related to voltage, current, frequency, etc.

Coming to electric vehicle refueling, or better said, charging, it is a different story altogether. The petrol/diesel dispenser is replaced by an Electric Vehicle Supply Equipment (EVSE).

The battery pack inside the EV, the Charging Management System and the Electric Vehicle Supply Equipment (EVSE)– all three of these must be compatible and understand a common language of communication. Before the charging starts, it has to be ensured that the current, voltage, wattage, etc. are compatible and there is no risk to the safety of the car or its occupants.

How are all of these aspects managed? The answer is- Electric Vehicle charging protocols/standards

We have a separate blog that discusses the need for such protocols and the challenges in EV charging. You can read it here.

EV Charging Protocols

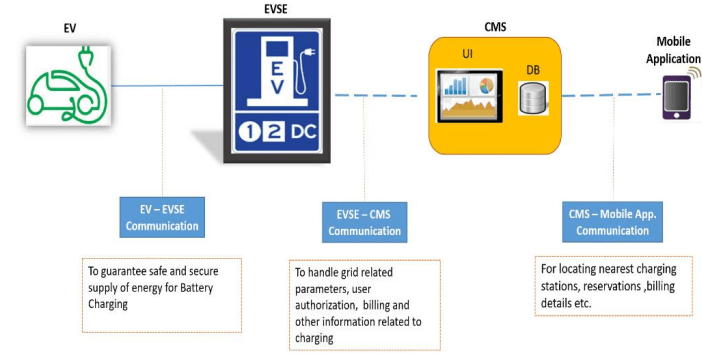

The communication between an Electric Vehicle and the Electric Vehicle Supply Equipment (EVSE) is based on certain Charging Protocols. Point to be noted here is that when we mention EVSE, it categorically implies public charging stations and not the regular AC charging sockets at home. Such distinction is important to mention as public charging also entails billing, an important factor to be considered. The charging protocols also manage the billing procedures.

Apart from billing, the role of EVSE is to ensure the safety of the car and the passenger during the charging. A threat can come in the form of unintended current flow, voltage fluctuations, or faults in the hardware inside the EV battery charging system.

The EV and EVSE manufactures and vendors require protocols/standards such as Bharat EV, CHAdeMO, CCS, etc. to enable safe connection between EV and EVSE.

These EV charging protocols or standards make sure that all the criteria of safe charging are fulfilled before the charging is initiated. They also monitor the vital parameters while the vehicle is being charged.

Since, there are several EV and EV charging system manufacturers spread across geographies, a number of EV charging protocols have also emerged.

One of these protocols that we will focus on in this blog, is specific to the Indian subcontinent. And hence the name, Bharat EV Charger (BEVC).

So before jumping to the implementation of BEVC, let’s first understand its finer details.

A Brief Overview of Bharat EV Charger Protocol

Bharat EV Charger (BEVC) protocol has been specifically designed for regulating the EV charging ecosystem in India.

This protocol supports both AC and DC charging with specifications clearly spelt out. A public metered AC outlet (PMAO) manages the AC charging with built-in billing module along with the safety and monitoring feature. AC charging (BEVC-AC001) is quite a slow mode of charging with a maximum current output of 15A. It is mostly used in low-powered EVs.

Compared to AC, the DC charging process is faster, and its implementation is also quite interesting.

So, let’s shift our focus to the DC charging specifications of Bharat EV standard and try to understand its implementation.

Understanding the Bharat EV Protocol Architecture

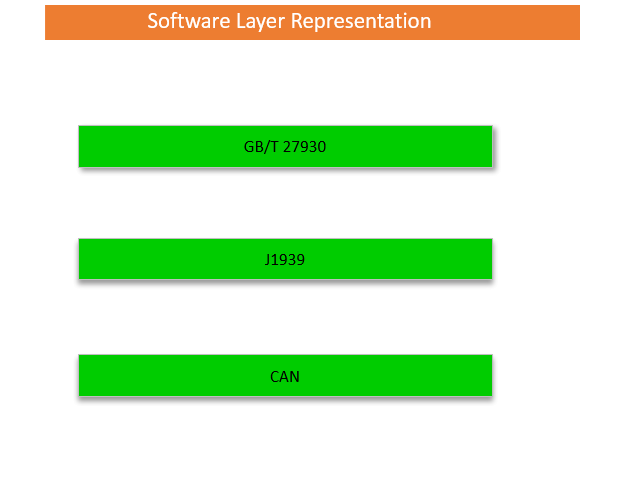

As per Bharat EV specifications, the communication between the EV and the Electric Vehicle Supply Equipment (EVSE) is powered by GB/T 27930 protocol that is based on SAE J1939 with CAN as physical layer.

GB/T 27930 is a protocol proposed by China Electricity Council (CEC). Its communication is based on SAE J1939, an in-vehicle communication protocol widely used in commercial vehicles as well as a few passenger vehicles.

Bharat EV Charger standard adapts the GB/T 27930 by creating its customized version. Customizing this protocol implies adding certain PGNs in an existing SAE J1939 protocol solution. We will talk about that part in the next section. For now, let’s take a look at the architecture of BEVC.

- Communication details for charger(EVSE) is as follows:

- The communication between the EVSE and battery management system (BMS) present in EV takes place with the help of GB/T 27930 with CAN as its physical layer.

- Communication between EVSE and central management system(CMS) of the power utility company is through the open charge point protocol(OCPP), which is basically utilised for billing and controlling the charge rate.

- Communication between user mobile and CMS is over the internet.

How Bharat EV Protocol is Implemented Using SAE J1939 Protocol Software

To establish the communication between the EV and the EVSE and initiate the charging, certain software requirements need to be fulfilled.

Software Requirement Between EVSE and EV:

-

- The EVSE and EV communicate with each other for exchanging the initial handshaking messages. The EVSE knows the type of EV battery using the handshake message. Also, in case the charge is being suspended, the reason is communicated to the EVSE.

- GB/T 27930 protocol uses some standard defined PGNs for communication between EVSE and EV.

Adapting the GB/T protocol for Bharat EV Charger standard requires the configuration of certain PGNs (Parameter Group Number) and the corresponding SPNs (Suspect Parameter Number) in the SAE J1939 protocol stack.

“PGN is a part of 29 bit identifier that is sent with every CAN message. For example, Engine Temperature is a Parameter Group identified by the number 65262. When an ECU receives a CAN message, it looks up the PGN in the identifier to understand the type of data sent in the message.”

“SPN is a unique number assigned to every parameter within a Parameter Group. In essence, it describes the parameter by providing certain information about the parameter. For example, SPN 110 is the Engine Coolant temperature; hence, it will be a part of the PGN that represents Engine Temperature (PGN 65262).”

SAE J1939 is a widely used CAN based communication protocol and also forms the basis of the GB/T 27930 protocol used in BVEC. Configuration of the required PGNs in the SAE J1939 makes it equivalent to GB/T 27930 while still retaining its uniqueness.

Let’s have a look at the PGNs and SPNs that are configured in J1939 protocol stack.

| PGN | SPN | USE |

| 9728(Charger Handshake Message(CHM)) | 2600 | To differentiate between pure GB/T and proposed Indian version of standard specification of BEVC. |

| 512(Vehicle and BMS Recognition Message(BRM)) | 2565 | To differentiate between the pure GB/T and Indian version of specification. |

| 2566 | To inform battery type | |

| 2567 | Informs power storage battery system of the whole vehicle with rated capacity | |

| 6400(BMS Suspending Charging Message(BST)) | 3511 | Informs the cause for BMS suspending the charging. |

| 3512 | Indicates the fault cause for BMS suspending the charging. | |

| 3513 | Conveys the error cause for BMS suspending the charging. | |

| 6656(Charger Suspending Message(CST)) | 3521 | Informs the cause for charger suspending the charging. |

| 3522 | Indicates the fault cause for the charger suspending the charging. | |

| 3523 | Conveys the error cause for charger suspending the charging. |

In addition to these PGNs and SPNs, few others are also configured as per the guidelines issued by the Government of India.

These PGNs can be configured to an existing J1939 protocol stack with the help of J1939 configuration tool and CAN IL tool. As PGNs are part of 29 bit CAN messages, the required PGNs and SPNs are added to the CAN messages required for EV and EVSE to communicate with each other.

Conclusion

SAE J1939 protocol software has been in use for several years now. Having an EV charger standard based on a proven vehicle communication protocol makes it more reliable and less prone to failure. Moreover, the tools for configuration of the required PGNs in an existing J1939 are also widely used and several automotive embedded development companies have such tools developed in-house. Bharat EV Charger standard, thus, appears quite promising in terms of making EV charging a less complicated affair. And in turn, it will steer more buyers towards electric vehicles.