If you are part of an R&D or IT team of an organization that is evaluating an IoT project, you may be able to relate to this situation:

- You have taken up the responsibility of Digital Transformation of the existing systems and processes. But you are finding it difficult to convince yourself and/or other stakeholders for a large scale IoT implementation across the enterprise.

- You are wondering how to demonstrate the benefits of this enterprise IoT project, with the help of a tailor-made solution & using actual data from your factory-floor or assembly. You desire to invest only 5-10% of the overall project cost, for this demonstration. Based on the results of the demo, your organization should be able to make a decision regarding investment in a full-scale IoT implementation.

These kinds of low-cost IoT designs (best suited for demonstrations) are known as Proof of Concept (PoC) solutions or Minimum Viable Products (MVP).

PoC solution development for IoT projects has become a preferred route of Digital Transformation for global businesses across domains like Automotive, Mining, Food Processing, Healthcare, Oil & Gas and other Industrial Automation use-cases.

In order to understand the reasons behind the (growing) popularity of IoT PoC development, we had a detailed conversation with Vidya Sagar, Head – IoT & Connected Car Solutions at Embitel Technologies.

Sagar has more than two decades of experience specifically in the domains of product engineering, Infotainment, Car HUD and Industrial IoT.

This blog is inspired by the insights we gathered during the conversation. It can serve as a guiding light for your IoT PoC development projects!

Q1. You have been collaborating with organizations from varied industrial segments & of different sizes. In your observation what are their objectives for implementing and investing in IoT?

Sagar: At a very broad-level, the objective of an organization to implement IoT projects would be to reduce the operational costs, or to improve customer service levels. These are achieved by continuously monitoring a network of devices and taking appropriate actions by making sense of the real-time data.

Having said that, at the micro-level, every customer has a unique way to define their objectives and will opt for a full-scale IoT implementation only if they are able to experience tangible benefits before a commitment is made.

Q2: From IoT Design to Development perspective, where does PoC development stand in the Bigger Picture?

Sagar: A well-defined Proof of Concept (PoC) is very crucial to demonstrate both the value & feasibility of your IoT solution, before proceeding for a full-fledged implementation.

It is recommended to also define the expected results that one aims to achieve through a PoC demonstration. Typically, a PoC can help you to demonstrate 70-80% of the objectives expected of the full-scale IoT implementation.

PoC design and development is an ideal solution to experience tangible benefits by investing only a fraction of the overall cost and efforts. Thus, a PoC can serve as a test specimen to ascertain how likely the actual implementation is to achieve the desired business goals.

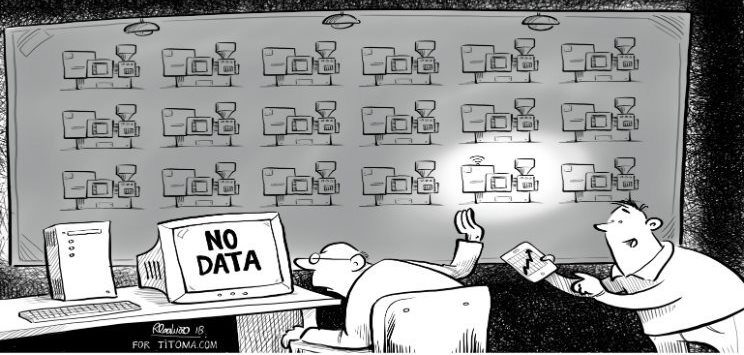

PoC development saves you from disaster during a full-fledged IoT implementation Source: Titoma.com

Q3. You mentioned that a PoC can help to demonstrate 70-80% of actual business goals. Can you explain this with an example?

Sagar: Let us consider the implementation of IoT in an Oil & Gas Industry as our example. Imagine that you want to implement IoT to check the overall oil loss occurring in a fuel delivery system. Here, you will have to analyze the project from the business and technical perspectives. You list down all the steps involved in forming the solution. You develop the PoC using the minimum hardware & software components to check if the IoT based solution is feasible or not. If you are able to demonstrate that the solution enables reduction of cost associated with an oil spill by at least 70% at the PoC stage itself, then it serves as sufficient reason to proceed with the full-scale implementation.

Q4. What are the critical design considerations that are often overlooked during PoC implementation?

Sagar: Let me elaborate on some PoC best practices. While starting a PoC design it is very important to focus on the end goals to be achieved. For example, let’s say it takes certain modules (software & hardware) to build a PoC. You assembled the modules, without envisioning the overall solution. Some of the PoC software and hardware modules were custom-made specifically to achieve a certain result. The PoC was successfully demonstrated and approved by the customer. Next, as you go for a full-fledged development, if the objective is changed then you have to discard all the modules used during the PoC development stage and start all over again.

This leads to too many complications. When you are starting afresh with new hardware and software modules (which are different from the components for your PoC), then it creates suspicion in the customer’s mind. They may not be sure if the new set up will manage to give the result, demonstrated during the PoC. Thus, it is always better to think of the final implementation before developing a PoC.

So, when you’re choosing hardware platform and software platform make sure it is more or less aligned with your actual IoT implementation goal & can be reused. Consider that in the PoC stage of an IoT project, I have to integrate a small microcontroller. I can do this using either the Raspberry Pi or Beagle Bone. And I write the PoC software code and import certain software libraries to execute the necessary actions. But after the PoC development, if I realize that these modules cannot be used for the actual implementation of the IoT project, then it’s a whole lot of wastage of money and time.

So, whatever you do in the PoC should be reusable when you do the actual IoT full-fledged implementation.

Q5. What are the steps involved in an IoT PoC development?

Sagar: The first and foremost thing that should be done before developing a PoC for your IoT project is a cost-benefit analysis.

- Cost-benefit Analysis to validate if the IoT implementation is worthwhile – Identify the business requirements and the desired results that the PoC is expected to demonstrate (which would be about 70-80% of the final business goal).

- Selecting the PoC software and hardware modules – This might involve a combination of off-the-shelf and custom-made modules.

- Preparing the setup for PoC development- This includes:

- Identifying the data collection points within the customer’s IoT ecosystem

- Development of the sensor nodes

- Development of the gateway device

- Integration of the communication model

- Choosing the ideal cloud platform (3rd party or any internal cloud server)

- Establishing connection with the cloud

- Connecting the IoT cloud with the user interface or dashboard

- Demonstrating the PoC to all the stakeholders responsible for approval of the IoT project.

Q6. Can you share some examples to explain more about custom module development for the PoC?

Sagar: Consider an example project in which you want to build an intelligent sensor node and a custom gateway which will cater to a specific protocol. Gateways are not much of a problem; but most of the time when it will comes to intelligent sensor node, the data collection point varies with the application. It could be as simple as measuring temperature and humidity, or it could be very complex like measuring the flow and quality of fuel/oil.

Based on the complexity you can choose the right hardware sensors and custom-build the intelligent sensor module. You can also plug in all the communication related protocols and build the Pilot project.

Q7. While developing the PoC, should one simulate the data or use actual data? What is your advice?

Sagar: I would say, during the PoC design and development phase you may feed some data through simulation. But during demonstration of the PoC, one should fetch the data from the real working environment. Usability will be a question if we use the simulated data so it’s better to use the actual data from the real operating conditions.

Q8. Ideally, how long does it take to develop a PoC for IoT applications?

Sagar: The general perception about the IoT development projects is that they can be completed within 3 to 4 months. But in practice, what we have seen is that it takes at least 6 months for the development itself and then another 4 to 6 months for the actual validation in the field on a pilot production. In a nutshell, it takes a good 12 to 15 months for a full-fledged implementation of IoT.

But with an IoT Proof of Concept (PoC), depending upon the complexity of the project, the minimum viability of the project can be assessed in just 2 to 4 months. PoC demonstrates Minimum Viability with Maximum Returns.

Q9. How do you evaluate the total cost of an IoT project before going for full-fledged production?

Sagar: Usually, the PoC requires about 10-15% of the overall investment of a full-fledged production. So based on the PoC development cost, you can evaluate the cost of the overall project implementation, to a certain extent. At around 15% of the overall project cost, the customer can validate his initial assumptions about the IoT project & identify if the results are close to what he intends to achieve.

Q10. Other than the feasibility analysis & design optimization factors, what benefit does a PoC development approach provide to customers implementing IoT in their business?

Sagar: In addition to the advantages we have already discussed, one of the prominent benefits of PoC from the customer’s point of view is a chance to validate and review vendor selection. This is one of the intangible benefits of going by the PoC way for IoT implementation. If you are not happy with the vendor before the production stage, then you can always change the vendor. The IP rights of the PoC is with the customer and hence he can approach yet another vendor if he wishes to, for final IoT project development.

We thank Vidya Sagar, Head – IoT & Connected Cars, Embitel Technologies, for sharing his valuable insights on the PoC implementation process.