Automotive Success Stories

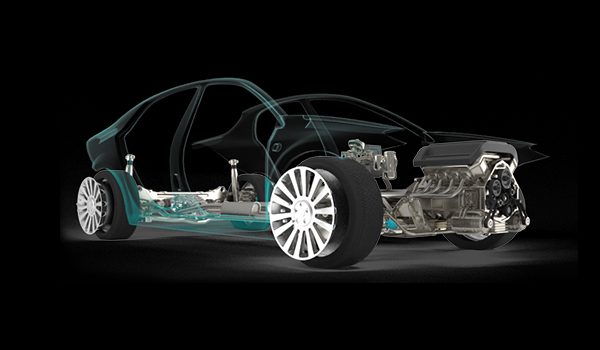

Whether it is collaboration for Electric Vehicles, Motor Controller Development or Functional Safety Consulting, we have always strived to create Value for Automotive OEMs’ and Suppliers.

Here are some of the Highlights of our Expertise:

- Model Based Development (MATLAB) and AUTOSAR

- Motor Controller Solutions

- ISO 26262 based Functional Safety Consulting

- Ready-to-Deploy IPs’ : UDS, OBD2, CAN FD, ISOBUS, CAN, LIN, J1939 and other stacks

All our Customer Success Stories are testimonies of our value-creation partnerships across the US, UK, Europe, India, China and South Korea.

Android Infotainment, Head-

Up Display & Instrument

Cluster

Up Display & Instrument

Cluster

Electric Vehicles, FOTA &

Others

Others

Motor Control and ECU

Solutions

Solutions

Functional Safety Consulting

(ISO 26262)

(ISO 26262)

Android Infotainment & Head-Up Display

Dual-display Android Infotainment Solution Development for an Electric Vehicle Startup

Integration of SAE J1939 stack with an Android Infotainment system | In-vehicle ECU communication

PoC Development of a Laser Based and Gesture Controlled HUD

J1939 Integration and Middleware Software Development for an Android Infotainment Head Unit Solution

The Success Story of How We Delivered a Digital Instrument Cluster for Electric

Electric Vehicles, FOTA & Others

ASIL-D Compliant Hardware & Software Development for Battery Management System

Development of Network Connectivity Interface APIs for 3-Wheeler Vehicle Control Unit

48V 6-Phase PMSM Hub Motor System for Electric Two-Wheelers and Three-Wheelers

Design and Development of Application Software for Vehicle Control Unit

Hub Motor Control for Electric Two Wheelers and Three Wheelers

Design and Development of Centralized Battery Management System with LiFePO4 Battery for EV Application

BMS Platform Software Development for Tier-1 BMS Solution Vendor

Development of Fault handling Application for Media Hub with MirrorLink and CarPlay Capabilities

Firmware Over-the-Air (FOTA) Update

and Bootloader Development for an Electric Vehicle

Development of AIS 140 Compliant FOTA Enabled Bootloader Module for a Tier-1

Supplier

Development of AIS 140 Compliant FOTA Enabled Bootloader Module for a Tier-1 Supplier

Motor Control And ECU Solutions

Development of Electric Vehicle Platform ECU with Focus on EV Motor Control Applications

Development of ASIL B Compliant Electric Vehicle MCU Platform Software

Building a Customizable LED Automotive Lighting Solution for an Automotive Tier-1

Software and Hardware Development for DC-DC Converter ECU

Development of Volkswagen Specific Bootloader Development for an Automotive Tier-1 Customer

Configuration and Integration Support for ECU Communication and Diagnostics Protocols in a Telematics System

Development Of Secure Bootloader For Automotive Tier-1 Customers

Electronic Control Units ECU Software Migration for a CV Client

Electronic Control Units ECU Software Migration for a CV Client

Smart Actuator for Turbocharger – ECU Software and Hardware Development project

An End-to-End Actuator Design Solution for a Throttle Control Unit (ECU)

Bluetooth Low Energy (BLE) Stack Integration with Seating Control Unit (ECU)

Motor Control Hardware and Software Development for an Electronic Power Steering (EPS) System

Bootloader Software Development Project for Automotive Control Unit (ECU) Application

Board Support Package Implementation and Configuration for Automotive Tier-1 Suppliers

Development of a Motor Controller and an Application Layer (using MATLAB), for a BLDC Motor

Development and Testing of Electronic Steering Column Adjustment System for an Automotive Tier-1

Functional Safety Consulting (ISO 26262)

Building an ASIL D Motor Control System Based on AUTOSAR architecture

Development of ASPICE Level 2 Automotive In-Cabin Air Quality Purification ECU

ISO 26262 Consulting for a Futuristic Electric Vehicle Project

Safety Analysis (FMEA, FMEDA) for ASIL C Compliant Automotive Lighting Solution

Tessy Tool Powered Unit Testing of ISO 26262 Compliant Automotive Software

Mutation Testing of an Automotive EPS for ISO 26262 (ASIL D) Compliance

Automotive Functional Safety Consulting and FMEDA for ASIL-B Compliance of a Motor Control System

Functional Safety Compliance Of Powertrain ECU for an Electric Vehicle

Functional Safety Delivered: ASIL-D Compliant Electronic Braking System for a Global Automotive Tier-1 Supplier

Functional Safety Delivered: End-to-End Development of an ASIL-D Compliant Electronic Braking ECU

Vehicle Networking &

Diagnostics

Diagnostics

Model Based Development

(MATLAB)

(MATLAB)

Autosar

Automotive Cybersecurity